Information from John Kincaide, President, 2ndLifeBatteries.com and WeRecycleBatteries.com

The explosive growth of solar over the last decade has led to uncomfortable realities that will affect the industry for decades to come — what will we do with systems once they reach the end of their lifespans? Just as plans are being implemented for solar panel recycling, so too comes the need for battery recycling and repurposing programs.

Lead-acid batteries already have established recycling programs, but lithium-ion batteries, which have dominated modern solar-plus-storage projects, currently do not and will soon need retirement plans of their own.

How can solar battery owners do the right thing? Responsible system owners should follow the “recycling mantra” as best they can:

- Reduce: Avoid over-scaling a system in an effort to accommodate future use and expansion. This will produce more waste to dispose of years later.

- Reuse: Repurpose what you can by selling used batteries to interested parties for second-life functions.

- Recycle: When nothing else can be done, recycle what is no longer needed, wanted or reusable.

This mantra is well-intentioned, but a mantra does not necessarily translate into meaningful action. Many energy storage managers do not formalize end-of-life recycling plans for their products since it’s not a personal concern. Recycling is “another person’s problem.” This attitude is discouraging.

The time for concern is now. Let’s explore how battery recycling works today, and how we can encourage more responsible solar-plus-storage end-of-life disposal practices.

Why is lead-acid battery recycling so common?

When consumers buy cars, they have paid for the lead in the car battery including, in effect, a future deposit when the battery is recycled. When they go to any lead-acid battery dealer to return a dead battery, the dealer will pay them up to $10. This consequently establishes a virtuous cycle, motivating battery owners to recycle their batteries. In Canada and the United States, lead-acid batteries have a 98 to 99% recycling rate because lead is infinitely recyclable without any degradation. It is the most recursively recycled material worldwide with 70% of all lead-acid batteries being made from recycled lead. Nearly every lead-acid battery component is recycled or made into useful products, including the plastics, sulfuric acid and copper.

When consumers buy cars, they have paid for the lead in the car battery including, in effect, a future deposit when the battery is recycled. When they go to any lead-acid battery dealer to return a dead battery, the dealer will pay them up to $10. This consequently establishes a virtuous cycle, motivating battery owners to recycle their batteries. In Canada and the United States, lead-acid batteries have a 98 to 99% recycling rate because lead is infinitely recyclable without any degradation. It is the most recursively recycled material worldwide with 70% of all lead-acid batteries being made from recycled lead. Nearly every lead-acid battery component is recycled or made into useful products, including the plastics, sulfuric acid and copper.

How does lithium-ion battery recycling compare?

There isn’t just one type of lithium-ion battery, so it’s important to understand which battery chemistry is being used. There are five major chemical formulations in the cathode or positive terminal of lithium batteries, and each formulation is designed for specific types of battery performance in different applications. Unlike lead-acid, there are no large metal plates in lithium-ion batteries that are easily recovered and smelted. The cathode is where most of the recoverable metallic compound value resides, along with trace amounts of lithium in the electrolyte. The valuable recoverable elements in these formulations are cobalt, nickel, lithium and manganese.

There are three lithium-ion types (LCO, NMC, NCA) that use different combinations of cobalt, nickel and manganese, and their lithium compounds have some residual value. Two lithium-ion battery types (LFP, LTO) have a negative value.

Unlike small lithium-ion consumer electronics batteries, large format lithium-ion batteries incur additional labor, hazmat packaging, transport and processing costs. If the battery module makes it difficult to extract the cells inside, the processing itself can exceed the value of the recovered components in the battery.

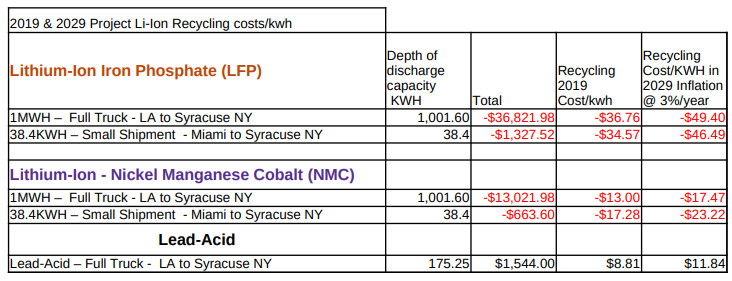

Starkly put, all lithium-ion batteries at current market commodity, labor, logistics and end-of-life processing prices will require an out-of-pocket recycling payment. Recycling lithium-iron phosphate (LFP) batteries is more expensive because the metal-compound-recovery value is negative. For example, 1-MWh of LFP batteries transported from Los Angeles to upstate New York for recycling would cost the battery owners $36.76/kWh. The same truck of NMC batteries would cost $13/kWh. In comparison, a full truckload of lead-acid batteries shipped from Los Angeles to upstate New York would actually profit $8.81/kWh.

Lithium-ion recycling costs look expensive compared to recycling lead-acid, which has been around for a long time. There are also multiple secondary lead-acid battery processing plants near major regional population centers across the United States, thus reducing transport costs. With an increased demand for recycling, it is hoped that more regional end-of-life processing plants will be built to handle lithium-ion batteries.

What does the recycling process look like for lithium-ion batteries?

Lithium-ion batteries are first frozen to -321°F with liquid nitrogen to prohibit combustion or explosion when the batteries are shredded. The flammable electrolyte is cleaned off and processed, and the cathode material is recovered.

Lithium-ion batteries are first frozen to -321°F with liquid nitrogen to prohibit combustion or explosion when the batteries are shredded. The flammable electrolyte is cleaned off and processed, and the cathode material is recovered.

There are two main types of recovery technologies used in lithium-ion battery recycling:

- Furnace processing: This method recovers the metals and requires removal of impurities through a slag-like process, and, unfortunately, the lithium compounds are captured in the “slag.” Recovering the lithium from the slag is cost prohibitive.

- Chemical processing (hydro-metallurgical): The cathode material is sent through a chemical process that separates the compounds, allowing them to then be purified, followed by refinement or chemical alteration into new compounds. Lithium compounds can be recovered and treated to be sold as lithium carbonate or lithium hydroxide, primary inputs for new lithium-ion batteries.

How can we get better at recycling batteries used in solar-plus-storage applications?

We don’t want powerful, flammable lithium-ion batteries stockpiled into forgotten warehouses. It is better to have the recycling cost included in the purchase price and saved and reinvested in a trust fund to pay for future recycling. When negative value batteries such as LFP become waste, it is much more difficult to ask customers to pay for dead batteries they bought many years ago.

Through California’s e-waste recycling program, the state has recycled 2.5 billion pounds of e-waste at a cost of $1 billion since 2005. This has all been financed by consumers and businesses through their original electronics purchases, where prescribed amounts were remitted to a state trust to pay collectors, transporters and recyclers to manage future e-waste. Hundreds of millions of pounds of negative-value old CRT televisions have been collected under this program.

Twenty-four other states have e-waste laws but don’t have a pre-paid program. This should change. With no plan in place to pay ahead for end-of-life recycling and no plan obligating manufacturers or installers to pay for it, the environment will soon receive a massive wave of toxic, highly flammable battery waste. A handful of companies are working hard to scale up recycling as fast as possible to meet the recycling demand.

What should today’s customers consider when purchasing batteries for solar projects?

As a consumer or business buying solar-plus-storage, be aware and knowledgeable of recycling requirements and plan ahead for them. It should be part of the business’ annual budget process. The trash can is not a viable option nor is it legal. Find a company like 2ndLifeBatteries.com or WeRecycleBatteries.com that can handle waste properly and take the responsibility to properly budget for it. There is a lack of understanding about how much it’s going to cost. Levelized cost of energy (LCOE) needs to include recycling. LCOE is not a true measure of the cost anymore because it does not include end-of-life processes.

As a consumer or business buying solar-plus-storage, be aware and knowledgeable of recycling requirements and plan ahead for them. It should be part of the business’ annual budget process. The trash can is not a viable option nor is it legal. Find a company like 2ndLifeBatteries.com or WeRecycleBatteries.com that can handle waste properly and take the responsibility to properly budget for it. There is a lack of understanding about how much it’s going to cost. Levelized cost of energy (LCOE) needs to include recycling. LCOE is not a true measure of the cost anymore because it does not include end-of-life processes.

Another important issue is that manufacturers of these products are not designing for recyclability. Some electric vehicle companies design new battery packs to meet UL standards for second-life. This is a great benefit, allowing second-life battery sellers to move the product more quickly into second-life solar systems. Too few companies are building this into their designs, and there will soon be a realization that this needs to happen on a wider scale.

Moreover, it’s our responsibility as an e-waste industry and for buyers of solar-plus-storage systems not to ship waste batteries to other countries under the guise of “reuse” or untested, uncertified second-life batteries. This type of irresponsible e-waste dumping activity has produced the toxic wastelands in China, Africa and South America.

John Kincaide is president of battery recycling businesses 2ndLifeBatteries.com and WeRecycleBatteries.com. With decades of computer software, computer-telephony and battery technical sales experience, John’s ability to actualize unforeseen business opportunities is the basis of his serial entrepreneurship. John’s vision is to extend the useful life of advanced batteries, realizing new value for all stakeholders.

John Kincaide is president of battery recycling businesses 2ndLifeBatteries.com and WeRecycleBatteries.com. With decades of computer software, computer-telephony and battery technical sales experience, John’s ability to actualize unforeseen business opportunities is the basis of his serial entrepreneurship. John’s vision is to extend the useful life of advanced batteries, realizing new value for all stakeholders.

The battery might have a second life but what about the third life. Can they be restored. With prices going sky high how can people pay for the costs to come and the waste that will come from the solar batteries? I’ m really concerned. Even for car batteries. Our world will be toxic from all the battery problems to come.

Hi Linda:

A 3rd Life is maybe possible for light-duty applications, such as powering lights. In fact, Skoda, a European carmaker has used second-life batteries from their electric vehicles, to do this kind of application for some of their car dealerships. They estimated 15 years of service for these batteries. It’s safe to say that for example, if the state of health (SOH) or (SOC) of Li-ion 10KWH that is being used for a 3rd-life application is possible. It could have 1000 cycles left and be only 40% state of charge, which means it has 4KWH capacity. Theoretically, at 80% discharge capacity (and that may be generous), it would still have 3.2KWH cycle capacity. Enough to power a small off-grid cabin with lights and a low power (600Wh/day) fridge, and a fan every day for 3-4 years. Value is more than cost in dollars – just having this capacity in a region in the world where there is no reliable grid power can be life-altering and possibly life-saving for the storage of medicines.

In my state, WI it has been extremely difficult to locate any information at all concerning lithium battery recycling or disposal. As best I have been able to find when batteries are deemed no longer viable for a site and are going to be discarded they become declared “hazardous waste” and then are governed under a confusing code mostly concerned with how they are transported to rightful avoid a fire in the event of a crash.

Our industry is going to require a lot more resources in the near future to deal with all the batteries we are going to have to deal with.

Steve, you are facing what a lot of others in the Solar and other industries are facing with LIthium-Ion end of life batteries.

Waste batteries are classified under US Federal EPA regulations, and not at the State level, although States and other jurisdictions may have additional requirements.

In the USA spent batteries are deemed by the EPA as “UNIVERSAL WASTE” and not “Hazardous Waste”. There is a big difference. Universal Waste regulations are not as burdensome and costly as “Hazardous Waste”.

Don’t be confused by the use of the word “Hazardous” when referring to US DOT Hazmat regulations with the EPA’s definition of “Hazardous Waste” – the are not the same.

Hazmat regulations regulate the safe and proper transport of hazardous goods and materials such as Lithium-Ion Batteries.

(Note: Hazardous waste (such as toxic industrial waste) can fall under the US DOT Hazmat transportation regulations – but that all together is a different subject and context).

Please call the US DOT Hazmat line at 1-800-467-4922 in Washington DC – free and valuable service – will give you the right answer to your questions. They cite the regulatons chapter an verse – but what is their great value is translating those citations into everyday language.

Written below is very generalized information as a rough guideline and not to be used as a replacement for the proper required training to ship Hazmat goods. Such training is required by DOT Regulations.

Lithium-ion batteries are deemed fully regulated under US DOT regulations when the Lithium-Ion battery is GREATER THAN 300WH (Watt-hours) or a single cell (or a single cell in a battery) is greater than 60WH.

The full legal shipping name on a Bill of Lading would be:

UN3480 Lithium-Ion Batteries, including lithium-ion polymer batteries Class 9 PG II

There are other variants of this legal proper shipping name for Lithium-Ion batteries packed in or with equipment. This would require purchasing Hazmat rated packaging. No – you can’t use a box from the grocery store – or other containers.

Lithium-ion batteries at 300 WH or less are still regulated but the packaging requirements are less stringent. As you said – this can get quite confusing very quickly, if you have not had Hazmat Training.

If the batteries are Damaged, Defective, or Recalled – then the DOT Hazmat Packaging requirements and shipping restrictions are much more demanding for safety.

Air transportation – in some situations is FORBIDDEN, and Never in Passenger aircraft – Cargo only.

If you have any questions, please contact a professional battery recycling service company such as ours.

I have a deep appreciation for your sentiment as a veteran in the recycling industry. Having spoken to countless contractors within the solar industry I’ve questioned why the burden of disposal, specifically the financial element, often falls on their shoulders. Introducing programs similar to those in California could help alleviate this issue at end-of-life.

Thank you, John and Kelly, for reporting on the importance of re-using and recycling lithium-ion batteries.

I appreciate how you make clear that batteries may have a second life after decommission. We must all work hand-in-hand to create a sustainable cycle that leaves minimal waste.

Between decommission and end-of-life, a robust solar aftermarket will fill the gap for resale and recycling. In my role at EnergyBin, I’m grateful to see that many solar companies, who have joined our B2B equipment trading community, are dedicated to building up the solar aftermarket. We still have a long ways to go, but it’s heart-warming to see what we can accomplish when we unite together.

But, as you point out, John, reusable equipment has to be quality product and safe, not e-waste. Members of EnergyBin, who sell reusable goods to qualified buyers around the world, advise that second-life equipment must have resale value. Otherwise, you’ll be hard-pressed to find buyers.