See also:

By John Connell, vice president of Crown Battery’s SLI Products Group

Maximize your battery life, avoid common mistakes and reduce costs by learning how to select the right battery for your system every time.

Did you know that batteries, even with nearly identical specifications, may have unequal life and performance? It’s true. Choosing the right model for your system can mean the difference between long project life, low maintenance and high performance — or frustrating downtime and early failure.

All batteries are made differently. Some manufacturers use heavier grids and more lead, robotic assembly and automated quality control, and exhaustive performance testing. Other manufacturers make batteries using manual assembly and outdated materials that can compromise performance. Low-price batteries seem like a bargain, but they often require more maintenance, fail earlier and cost more in the long run.

By asking the right questions, you’ll be able to identify differences in design, materials, manufacturing and quality control to choose the best battery for you.

Understand Different Battery Types

The first step is to select the right type. Lead-acid batteries are made for specific applications, and some aren’t a good fit for renewable energy (RE) systems. Automotive and commercial starter batteries deliver short bursts of power and stay at full charge most of the time, making them unsuited for such applications. Uninterruptable power supply (UPS) batteries are designed to provide backup electricity during power outages but will not tolerate continuous discharge and charge cycles.

Deep-cycle batteries deliver electricity for a long time, even multiple days, because they’re designed for constant discharge and charge cycles. The difference between deep-cycle and RE-specific batteries is that RE batteries’ basic design accounts for the specific requirements of renewable energy applications.

Flooded batteries are the most commonly used batteries in RE and grid-backup systems, because they’re affordable, easy to maintain, long-lasting and reliable. Valve-regulated lead–acid (VRLA) batteries, such as absorbent glass mat (AGM) and gel, are maintenance-free but typically more expensive. Whatever type of battery you choose, know which materials, construction methods and quality control systems translate into affordable, reliable power for your system.

Acid recirculation systems use computerized vacuums to circulate acid through batteries, reducing heat for longer life. Photo courtesy of Crown Battery Manufacturing

Materials And Manufacturing Matter

A battery produces electrical current through a reaction that converts its stored chemical energy into electrical energy. This process starts in the lead itself. Most manufacturers in the North American battery industry use recycled lead, so the performance and lifespan differences between lead in the batteries come from the amount of lead, additive formulation, lead-oxide production methods and quality controls employed by producers.

Metal grids that hold lead paste make energy storage possible. Thicker, heavier plates withstand corrosion longer and hold more lead for chemical reactions, so they increase battery life. But raw lead prices have skyrocketed since 2006, and since lead comprises 60 to 80% of a battery’s cost, there’s pressure to cut corners to offset raw material price hikes.

Manufacturers that understand the importance of quality still produce a superior product. They do not try to cut costs through cutting back on key materials like lead, but by improving manufacturing efficiency and using of active lead materials. Ultimately, more lead and advanced manufacturing save customers money because they don’t have to replace their batteries as often.

Even grid production methods affect life. Some manufacturers use expanded metal and stamped grid production because they’re quicker, but these methods embed impurities and porosity into grid wires. In contrast, grids produced by gravity casting contain no impurities and near-zero porosity. Gravity-cast plates extend life and improve reliability.

Active lead material is applied to plates in a process called pasting, and dozens of variables in paste mixing significantly affect battery performance. In conventional systems, these variables are adjusted by hand and paste is only as good as its operator. Computerized paste mixing alleviates these problems by instantly adjusting variables.

Once grids are pasted, they’re cured (dried in specialized “curing ovens” at a particular temperature and humidity) to bond active lead materials to the grid for better performance and longer life. Look for batteries built with plates prepared in curing ovens, which optimize important variables such as temperature and humidity at every stage of the curing cycle to ensure all plates deliver optimal capacity and service life.

After curing, battery plates are stacked in groups and connected by fusing the plates together with a lead strap that creates a parallel circuit between the plates. Many companies still use strap-assembly processes that originated in the first half of the 20th century because they’re economical. Workers manually attach lead lugs to a strap and burn them together one-by-one using a torch and lead stick or by manually pouring molten lead around a jig. Manually welded straps have weaker connection points.

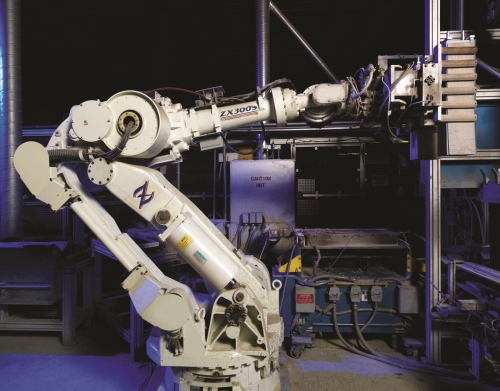

Other companies use cast-on-strap (COS) assembly systems that fuse battery plates together simultaneously at the optimal temperature. Because COS allows for 4,000 adjustments versus only 40 for hand welding, it ensures consistent, low electrical-resistance welds that strengthen connections, resist cracking and improve battery life. Robotic COS assembly also prevent failure modes that are common with manually-assembled batteries, such as “lead run-down” between plates, and allow for features that reduce corrosion, increase current and reduce maintenance costs.

Robots load plates in this computer-controlled production system, for increased precision and lifespan. Photo courtesy of Crown Battery Manufacturing

Properly integrating the COS process can be expensive and time-consuming. Make sure your battery manufacturer has had time to refine its COS system. If a company advertises using COS, make sure to ask if it produces 100% of its offerings using COS manufacturing.

Following assembly, batteries are charged for the first time in a process called formation that converts lead sulfate and ensures maximum capacity. Some companies “speed up” formation using higher currents, which cut production time at the expense of active (usable) material and lifespan. In contrast, lower current over a longer time always results in longer life.

Recognize Quality

Quality control should be built into all stages of production to improve product quality and consistency. In more advanced plants, this includes machine testing for short circuits, along with computerized welding and heat sealing. Some battery companies even use vision systems (image capturing and advanced software that automatically inspect parts) to spot defects humans can miss.

Battery manufacturers should monitor every stage of production with a combination of trained employees and computer systems. Photo courtesy of Crown Battery Manufacturing

An on-site lab tests batteries to ensure performance and consistency. Photo courtesy of Crown Battery Manufacturing

When you know what to look for — and what to avoid — in a renewable energy battery, it’s much easier to find the best model for your needs. To compare manufacturing techniques and materials and get a better idea of which batteries will perform better and last longer, visit your RE battery manufacturer’s website or call the manufacturer or your distributor.

John Connell is the vice president of Crown Battery’s SLI Products Group. Crown Battery manufactures all batteries at its Fremont, Ohio plant.

THIS article is poorly titled. It has little to do with selecting a battery system and is merely a survey of battery types.

What about using LiFePo4 (Lithium Iron Phosphate) batteries instead of lead-acid batteries in residential PV systems? Is LiFePo4 ready for prime time?