This article was updated May 2018.

See also: What are the common battery types used in solar+storage projects?

Interest in energy storage is growing rapidly. It’s not all about living off the grid anymore. Storage helps solve variability issues with renewables. Adding a solar battery to a grid-connected residential project also allows the array to keep providing power to critical loads when the grid is down, instead of having to disconnect and refrain from generating power. Storage can also help commercial consumers reduce peak demand charges, significantly lowering their energy bills. Storage is even used at the utility level to help provide ancillary services to the grid. The need for storage grows as states pass self-consumption and other legislation that promotes the use of batteries. .

Batteries in solar applications have to meet the demands of unstable grid energy, heavy cycling (charging and discharging) and irregular full recharging. There’s a variety of battery types fitted for these unique requirements. Considerations for choosing a battery include cost, cycle life and installation and maintenance.

Here’s a look at these aspects of each technology, as well as some best practices when selecting batteries for a solar installation.

Solar battery technologies

Lead acid

Deep-cycle, lead-acid batteries have been employed in renewable energy and reliably used in off-grid applications globally for decades.

Cost: Typical deep-cycle, lead-acid batteries cost significantly less than lithium-ion.

Cycling: Valve-regulated lead-acid (VRLA) batteries include absorbed glass mat (AGM) and gel models. Many AGM batteries available in the market are primarily built for dual-purpose or standby applications like emergency backup, but not deep cycling. However, new deep-cycle AGM designs have increased performance and total energy output making them a good choice for renewable energy applications at a lower price point than gel batteries.

In fact, VRLA batteries with added nanocarbon are more resistant to sulfation, which can lead batteries to die over time. The carbon slows sulfation and allows the battery to charge faster and cycle more than traditional lead acid. This makes it a good choice for applications in which the battery is in a partial state of charge, such as energy arbitrage or off-grid.

Replacement/maintenance: Many factors including initial design and ongoing maintenance influence battery life so it’s difficult to put a time frame on when the batteries will need replacement. Flooded lead-acid batteries have to be refilled regularly because the electrolyte that fully submerges the battery plates evaporates during charging. The battery enclosure needs ventilation to keep hydrogen gas from accumulating to dangerous levels.

AGM and gel technologies, however, are recombinant, meaning they internally convert hydrogen and oxygen into water and do not require maintenance. As there is no free acid inside these batteries, they can be installed in any position other than upside down. Because solar applications can be in hard-to-reach or remote areas, the ability to install the batteries and let them operate over long periods without maintenance is a benefit.

Disposal: Proper disposal of lead-acid batteries is important because they are toxic. Thankfully, the automotive industry organized to recycle lead early on. Plastic containers and covers of old batteries can also be neutralized, reground and used in new battery cases. In some cases, the electrolyte is cleaned, reprocessed and sold as battery-grade electrolyte. In other instances, the sulfate content is removed as ammonium sulfate and used in fertilizers. The separators are often used as a fuel source for the recycling process. Old batteries may be returned to the battery retailer, automotive service station, a battery manufacturer or other authorized collection centers for recycling.

Lithium-ion

Lithium-ion

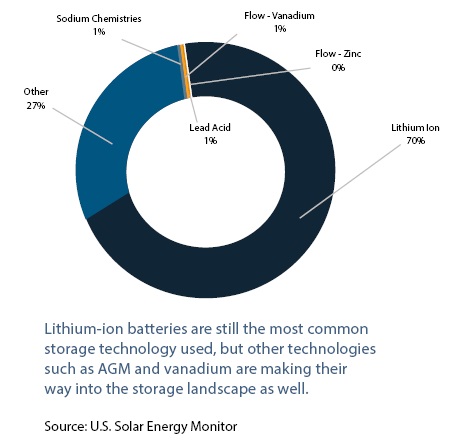

According to a U.S. Solar Energy Monitor report, lithium-ion batteries are the most common storage technology, regardless of application. There are three types: pouches such as in smartphones and tablets, cylindrical such as in power tools, and prismatic (which come in various shapes) such as in electronic vehicles. Prismatic types often have corrugated sides, which create air gaps between adjacent cells and can aid in cooling. The prismatic can have applications in solar energy storage, specifically lithium iron phosphate (LFP) batteries.

Cost: Deutsche Bank analysts estimated lithium-ion batteries at about $500/kWh at the end of 2014, but one manufacturer said it’s closer to $750 to $950/kWh. Overall, they are more expensive than lead acid batteries. Part of this cost comes from needing a battery management system to monitor the voltage and temperature of each cell to prevent excessive charging and discharging. A BMS isn’t critical for other technologies like lead acid because the inverter or charger controller can handle the battery charging regime. However, some manufacturers note that, if sized correctly, lithium-ion cells can reduce the cost of peripheral devices like charge controllers, offsetting its higher initial price and lowering cost-of-ownership.

Cycling: Lithium-ion batteries can typically deliver more cycles in their lifetime than lead-acid. This makes them a good choice for applications when batteries are cycled to provide ancillary services to the grid such as energy smoothing or frequency and voltage support. The most important benefit lithium-ion provides for solar is its high charge and discharge efficiencies, which help harvest more energy. Lithium-ion batteries also lose less capacity when idle, which is useful in solar installations where energy is only used occasionally.

Replacement/maintenance: Lithium-ion batteries can be lighter and more self contained than lead-acid batteries, so may be easier to install and change out. They can be wall-mounted and located indoors or outdoors. They are solid, so don’t require refills or maintenance.

Disposal: Lithium-ion batteries can use organic or inorganic cells. Organic-based batteries are free from any toxins. Inorganic-based cells are much more difficult to dispose of. Inorganic lithium-ion is toxic so it must be disposed of properly. Manufacturers encourage recycling, but there is often a price. Spent lithium-ion cells have little commercial value. Lithium-ion manufacturing involves lengthy preparation and purification of the raw material. In recycling, the metal must go through a similar process again, so it’s often cheaper to mine virgin material than retrieve it from recycling.

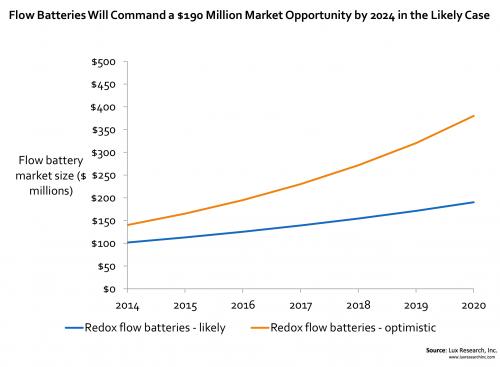

Flow batteries

Flow battery use in long duration storage is growing. Most conventional flow batteries use two electrolyte liquids: one with a negatively charged cathode, and one with a positively charged anode. The cathode and anode are separated into two tanks by a membrane, because if they come into contact with each other the battery will short and require replacement. This is often what happens with lithium-ion batteries; the membrane degrades over time. But the exchange of negatively and positively charged fluids in flow batteries produces electrical current without degradation, providing a longer cycle life and quick response times.

Cost: When looking the levelized cost of storage, flow batteries often come out on top in long-duration storage applications over lithium ion. This is due to their ability to last decades with little maintenance and the fact that the electrolyte materials can be reused or sold.

Replacement/maintenance: The flow battery’s membrane degrades little over time, allowing flow batteries to last much longer than other technologies. Flow batteries also require little maintenance. With other technologies, adding more batteries is the only way to increase hours of storage. A benefit of flow batteries is that you can increase storage capacity by simply adding more electrolyte.

Cycling: Flow battery developers say the technology has no cycling limitations, and batteries can be charged and discharged completely without impact on their lifespan.

Disposal: Though it depends on the chemistry, flow batteries tend to be less reactive and easy to dispose, with no fire risk. Many times the electrolyte is able to recycled, which helps lower the levelized cost of storage for flow batteries.

Nickel cadmium

Nickel cadmium or NiCd batteries have been around since the early 1900s. Though they may not have the energy density (the power) of other technologies, they provide long life and reliability without complex management systems.

Cost: Nickel cadmium is relatively inexpensive compared with other technologies.

Replacement/maintenance: NiCd batteries are vented to allow gases to dissipate. They traditionally require some watering, but new designs allow the gases to recombine to form water which makes the battery nearly maintenance free. This, along with the ability to tolerate extreme temperatures, makes these batteries ideal for off-grid applications in harsh environments. They have been used for storage in megawatt-sized projects. .

Cycling: NiCd batteries are rugged batteries with a high cycle life. Some companies promise a service life of up to 20 years.

Disposal: Cadmium is a hazardous material. In fact Europe limits the applications NiCd batteries can be used in. Toxic materials must be removed before the battery is disposed of. NiCd batteries can be recycled, however. The cadmium can be extracted and reused in new batteries. The nickel can be recovered and used to make stainless steel.

Choosing the right battery

Use a sizing calculator

Battery sizing is essential but often overlooked by users and installers. Batteries in PV systems are routinely undersized due to cost or because the system loads were underestimated. It’s important to know the customer’s power needs and correctly plan. Many online calculators provided by battery manufacturers and other software simplifies determining battery capacity for load requirements.

Consider cost of ownership

There are several factors that should be taken into account when determining the total cost of ownership over the life of the battery.

• Price: A battery with a low price is always attractive, but if low price comes at the expense of quality and battery life, the need for frequent battery replacements could boost the cost over time. That’s why it’s important to consider issues other than price when making the decision.

• Capacity: Battery capacity is important because it’s a measure of the amount of energy stored in the battery.

• Voltage: The battery bank voltage must be considered to ensure it matches the system requirements. The battery bank voltage is often determined by the inverter specifications if installing a DC-to-AC system or by the voltage of the loads in a DC system.

• Cycle Life: The most critical consideration is cycle life, which provides the number of discharge/charge cycles the battery can provide before capacity drops to a specified percentage of rated capacity. Batteries from different manufacturers may have the same capacity and energy content and be similar in weight. But design, materials, process and quality influence how long the battery will cycle.

Battery ratings

The nameplate rating on a battery is the fully developed capacity, so it can be misleading to test a battery immediately after it is purchased because it may take up to 100+ cycles for it to reach its full capacity. Beware of batteries that promise full capacity at the time of purchase or those that reach full capacity after only a few cycles. Batteries with a 100+ cycle warm-up will always outlast those touting a high initial capacity.

For more on batteries & storage, see more recent articles here.

LiFePo4 battery will be the best choice for energy storage. the cost drops alots during these years development on EV industry. the OEM factory price is around 450usd/ kwh at the moment

I have a opportunity to purchase NiCad batteries that were used in Rav4EV, For rangerEV,and Chevrolet S10EV vehicles.

There are approximately 300 of them available. I expect these will not have a 100% of there original storage capacity, but I’m told they have 60-80% of the original capacity.

Will this type of battery be compatible for solar power storage?

Any advice is appreciated

Here is a story we did a few years back on reusing EV batteries in solar projects: https://www.solarpowerworldonline.com/2017/02/giving-electric-vehicle-batteries-second-life-solar-projects/

Hi James,

I came across your post – I am currently looking at getting an chevrolet s10 ev, though currently the batteries are dead. Did you end up getting some of those batteries? and would you be willing to sell them?

Wonderful article, I never knew the history of batteries without reading this article and comments below.

Lithium Battery is the best option.

The lithium batteries allow the complete discharge, that is to say, of 100% of its power. For example, a lithium battery of 200Ah can be charged 100%, unlike others such as AGM or gel do not allow loads greater than 80/90%, then not fully discharged.

And it is this feature that makes the charging process faster than other types of batteries. In addition, it allows several download processes (up to 6000 cycles at 90%).

Another advantage of lithium batteries is their internal management system and uninterrupted service. That is, they have an autonomous power supply that is activated in case of a cut in the main power supply.

The battery industry has expanded in the last 20 years, with demands of more power density in smaller packages driven by the personal electronics boom. Now the push for all electric vehicles is pushing the envelope once again towards more energy density, (safer) operation and longer battery life for less money per kWh. If the price per kWh of storage gets low enough, then designing a system for one’s personal use can actually be “over designed” for system longevity. At that point you have installed a legacy power system for future generations to use. The next big thing for home energy storage may well be the so called solid state battery. Even IF the battery is not as energy dense as some Lithium/ Cobalt/ Magnesium battery technology, for static energy storage for one’s home or business, the size of the storage unit is less of a concern.

I am looking at a property in Georgia that has Gould NCX-840 batteries that were used to store power from a water wheel generation application. The water wheel is no longer used for power generation. The age of the batteries at this time are unknown. The batteries are on racks and appear to be in good condition. is there a market for these? Is there a application that these may be used? if these are of no use where can they be recycled? These batteries are of concern and a stumbling block on the purchase of the property. please let me know if anyone has any suggestions.

Swell Energy is the first to offer the LG Chem lithium-ion battery in the US. http://www.swellenergy.com

You left out NiFe batteries which are a lot better that most people think. The “myths” say they are NOT efficient chargers. Their charging efficiency is about 90-95% up to 50-60% of capacity, decreasing as you approach 80%. Of course the last 20% only has an efficiency of 50%.

Unlike Lead Acid and Lithium, they are not a serious environmental hazard. The demand for Lithium batteries is doing a great deal of damage (and poisoning of everything in the area) in the locations where the metal is mined and refined. Lead is always a problem as it cannot be mined, smelted or recycled without inescapable dangers.

NiFe batteries also have no “memory effect ” and are not drastically harmed by being fully discharged (though I’d keep them over 20% just to keep them in really good condition). They can also be overcharged without harm, and last 40+ years. Full discharge and over charging will mean topping up the electrolyte.

Unlike other battery banks choices, because they do not lose major function over time, you can add on to your bank as your needs increase (or your budget allows) without screwing up the entire bank (and good luck on that with lead or lithium). NiFe banks are made of ‘individual cells’, not of several batteries (of cells), which means if a single cell fails you can replace IT instead of one (or more) batteries. NiFe also lets you get up to 50% more usable ampere hours per cell than lead acid does. They are also unharmed by the cold.

Also most battery bank systems have to be oversized because you damage the battery if you reduce the charge too far. With a lead acid battery, it’s recommended to use only 20-30% of the total battery capacity to get 5 years of life. With Li batteries you need to NEVER run them them below roughly 30% max charge, or you damage their life span a lot. How much use do you get from a bank, if you can’t use the power? Making sure this does not happen means you CAN’T use all the energy in your battery bank and you need a charge controller too (although that is always a good idea anyway).

NiFe batteries accept and withstand overcharge and over-discharge (extreme deep cycle), with an average efficiency of around 80% over their life (depending on system set up). They can also remain discharged for long periods without damage. Lead Acid batteries need to be stored in a charged state. This means your LiFe bank can be “forgotten” for a while (at your cabin at the male), without destroying it, though I have read that it is a good idea to totally change your electrolyte every 8 to 10 years (instead of buying an entire new battery bank every 6 years).

To be VERY frank for a moment… in the old days these batteries were solid iron plates and solid nickel plates. From what I understand the new production runs (post 1970s) of these cells are only nickel plated instead of solid nickel (grumble). I do know that the old original solid plate Edison batteries run for a very long time and are hard to hurt. It is hard to be certain of their life span…BECAUSE there are 80+ year old systems that are still working. I recently read a homesteading blog where a fellow got a bunch of the originals that were sitting at a scrap yard. They were empty of electrolyte and quite old. The addition of new electrolyte had them working again. Try that with a lead acid battery.

Some batteries do need the occasional “top up” of electrolyte. This is safer with NiFe because you are not dealing with concentrated acid, or possible hydrogen gas. Not also that there are tons of different batteries around, and the many wet/flooded technologies all need electrolyte maintenance…however this brings up the concept of OBTAINING more electrolyte (especially in 20 or 40 years when the tech will have all changed). However NiFe batteries (which do need a top up… more often if you run them flat and/or over charge them often) use an easy to find substance as the electrolyte. They can run on just KOH in distilled water (so find a soap making supply house), but run better on the modern mix of KOH, LiOH & distilled water, which one can obtain and mix DIY. In fact a lot of NiFe batteries come without any electrolyte in them (a lot less weight) and come with an electrolyte kit with instructions on how to make it yourself (of course you can always call a local company to do it for you). That said, if you managed to pass your year 7 science class, it should not be a problem.

* COST *

Yes there is a cost difference. As always you can buy yourself (for instance) a $15 drill and then buy another 18 moths later when it no longer works…by a $40 drill and get a new one in 5 years, or you can buy an $80 drill and never buy another one. Many things are like this. A lower initial outlay, does not necessarily save you any money (even over a couple of years). Most of your Li and Pb based batteries are going to be dead in 6 years (less if mistreated). I’m 52 so, a bank of NiFe batteries (especially if treated nicely) could last longer that the rest of my life span.

As for actual prices today (Sep 20 2015), I am looking at an ebay site that sells (not including shipping, a 12 volt, 1500 amp/hour, 18 Kw/Hour bank (which could be wired differently for 24 of 48 volts) for about $9000 Australian ($6500 USD). God only knows what warranty they might have (ebay… shudder).

An “IronCore” NiFe systems comes in at about $9100 for the same size bank (with 6 year pro rata replacement warranty).

Iron Edison’s are more expensive, but very well tested. Their 48 volt batteries at 14.4 Kwh bank is about $14,655 USD. Of course the warranty on each is different. Their warranty says :

—– quote —–

Iron Edison Battery Company will guarantee that the Nickel Iron battery sold under this agreement will provide 70% of the rated Amp hour capacity at 10 years from date of delivery. This guarantee assumes proper installation, a max depth of discharge of 80%, regular watering and electrolyte changes.

—– end quote —-

You would probably get better performance than that, and a lot longer life, but I can see how they would want to cover their butts. After all “Craftsman” is the only company I know of that sells ANYTHING with a life time warranty.