By Hanan Fishman, president, Alencon Systems

While installing batteries into an existing PV array using DC coupling makes a lot of sense, it always looks easier on paper, according to Tom Fenimore, business development for Duke Energy.

“One of the challenges for executing a DC-coupled retrofit of storage into an existing PV plant is understanding and dealing with the wiring practices of the existing site and all of the physical infrastructure. It’s always easier on a block diagram. Once you get into the field it can be more challenging to make it all work,” Fenimore said.

One such unforeseen challenge, the issue of incorporating floating batteries into a grounded PV array, arose at a storage retrofit Duke Energy executed in 2019 at its McAlpine Solar plant.

“We ran into the problem of DC-coupling storage with positively grounded solar panels. Overcoming that challenge required the installation of Alencon Systems’ galvanically isolated DC optimizers to create a floating ground between the PV systems and the batteries. That was completely unexpected when we started,” Fenimore said. “Initially, we thought we could overcome this problem by just making changes at the inverter level. It turned out the only solution was creating isolation between the PV array and the batteries. The era of the solar modules’ manufacture can complicate the installation of storage into an existing PV array.”

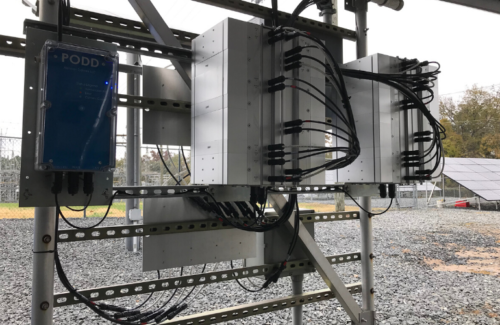

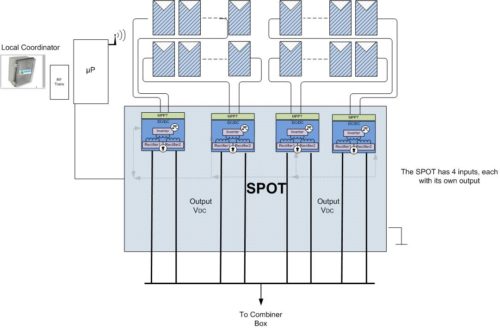

In 2019, Duke Energy deployed a DC-coupled solar + storage project where it installed a battery storage system into an existing PV array. One technical key to doing so was installing Alencon’s galvanically isolated DC-DC optimizers to isolated the positively ground PV system from the floating batteries on a common DC bus.

How galvanically isolated DC-DC optimizers facilitate retrofitting storage into existing PV plants

As mentioned above, one of the technical lessons learned by Duke Energy in its last DC-coupled storage retrofit is the need to isolate the grounding of the PV system from the newly installed battery. This is not generally an issue with AC-coupled solar + storage systems as the individual inverters behind the PV and batteries create this grounding isolation automatically.

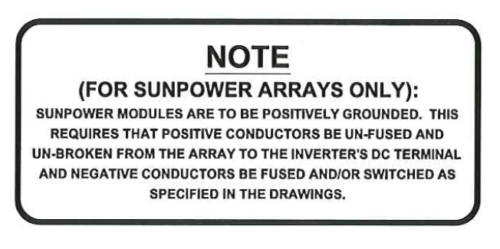

Installed PV systems, particularly those connected to central inverters, are typically grounded. In many cases, installed PV systems are negatively grounded. In the case of Duke Energy’s recent McAlpine project, the existing PV plant had an older model of SunPower panels that had a positive grounding requirement. PV panels may need to be grounded for any number of reasons, including the need to maintain their performance over 25 years and guard against conditions like potential induced degradation (PID).

A typical call-out on as-built drawings on older, installed PV systems with SunPower panels. Such call-outs indicate the importance of maintaining the array in a positive grounded configuration. Batteries are generally required to float for safety purposes.

On the flip side, battery storage systems need to have floating grounds for safety purposes. Specifically, this requirement is necessary with large battery systems because having a floating ground allows for two faults to occur for a serious safety situation to arise. By allowing for two faults, the first fault can be detected by the on-board fault detection systems and safely disconnect the battery before a problem occurs. With all the attention being given to energy storage system fires, heeding the safety guidance of battery manufacturers is critical.

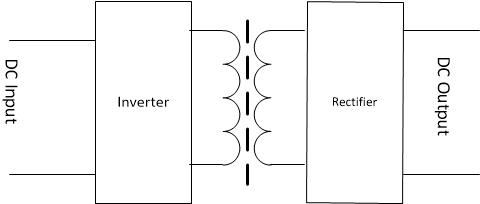

Galvanic isolation is used where two or more electric circuits must communicate, but their grounds may be at different potentials. Alencon Systems’ DC-DC converter consists of an inverter and a rectifier section with an isolation transformer between them to achieve full galvanic isolation between input and output. The application of silicon carbide power electronics allows Alencon’s devices to be very efficient and small.

Galvanic isolation is used where two or more electric circuits must communicate, but their grounds may be at different potentials. Galvanic isolation is an effective method of breaking ground loops by preventing unwanted current from flowing between two units sharing a ground conductor. When DC coupling solar and storage, a DC-DC converter is required to map the voltage differences between the PV system and the battery. A galvanically isolated DC-DC converter, such as those manufactured by Alencon Systems, serves the dual purpose of mapping PV voltage to battery voltage while isolating the differential grounding schemes that could be present. Alencon’s products are able to achieve this benefit in a highly compact and efficient package through the application of cutting-edge silicon-carbide power electronics.

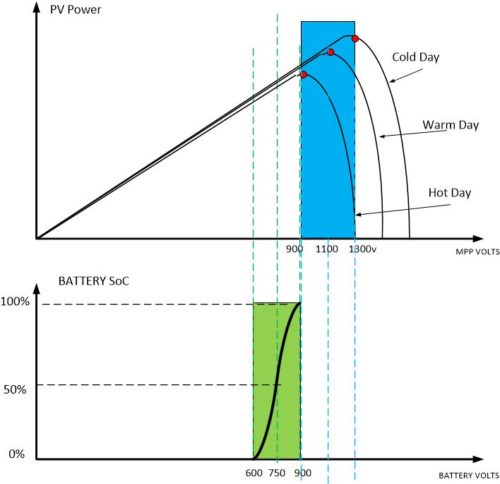

Alencon’s DC-DC converters serve to map the differential voltages between PV systems and batteries placed on the same DC bus. This mapping is demonstrated above.

Adding storage to solar projects is the next frontier in the clean energy revolution, but it’s not without technical challenges. Fortunately, commercialized, scalable technological solutions exist to solve these problems.

Tell Us What You Think!