By Douglas Grubbs, applications engineer, Morningstar Corporation

In its basic forms, solar PV is a very straightforward proposition. Hook a solar panel up to a DC load and it will run until the sun goes down. Connect solar panels to a grid-tied inverter and, as long as the sun is shining, power will be sent to the utility. It’s all fairly easy — until the sun stops shining.

Where it starts to get more complex is with energy storage, for use when the sun isn’t shining or when the grid is down. Storing electricity to do useful work later requires batteries connected to a solar PV system. Once a battery is added, a charge controller becomes one of the most important system components.

Anyone going off-grid or wanting to use a hybrid system that can sell solar-generated electricity during the day and store that power for use at night, during an outage or during peak times will need a solar charge controller.

What a solar charge controller does

Think of a solar charge controller as a regulator. It delivers power from the PV array to system loads and the battery bank. When the battery bank is nearly full, the controller will taper off the charging current to maintain the required voltage to fully charge the battery and keep it topped off. By being able to regulate the voltage, the solar controller protects the battery. The key word is “protects.” Batteries can be the most expensive part of a system, and a solar charge controller protects them from both overcharging and undercharging.

The second role can be more difficult to understand, but running batteries in a “partial state-of-charge” can shorten their life tremendously. Extended periods with a partial state of charge will cause the plates of a lead-acid battery to become sulfated and greatly reduce life expectancy, and lithium battery chemistries are equally vulnerable to chronic undercharging. In fact, running batteries down to zero can kill them quickly. Therefore, load control for the connected DC electrical loads is very important. The low voltage disconnect (LVD) switching included with a charge controller protects batteries from over-discharging.

Overcharging all types of batteries can cause irreparable damage. Overcharging lead-acid batteries may cause excessive gassing that can actually “boil” the water away, damaging a battery’s plates by exposing them. In a worst-case scenario, overheating and high pressure can cause explosive results upon release.

Typically, smaller charge controllers include a load control circuit. On larger controllers such as the Morningstar TriStar, separate load control switches and relays can also be used for load control of DC loads up to 45 or 60 Amps. Alongside a charge controller, a relay driver is also commonly used to switch relays on and off for load control. The relay driver includes four separate channels to prioritize more critical loads to stay on longer than less critical loads. It’s also useful for automatic generator start control and alarm notifications.

More advanced solar charge controllers can also monitor temperature and adjust battery charging to optimize the charging accordingly. This is referred to as temperature compensation, which charges to a higher voltage in cold temperatures and a lower voltage when it is warm.

Many solar charge controllers include on-site and remote data monitoring. Morningstar offers serial communications options so the controllers can be monitored locally or remotely with compatible communications equipment. In addition, Ethernet communication capability is also available for monitoring locally on a LAN or remotely over the internet.

For these and other reasons, the solar controller can be thought of as the system’s heart and brains. It ensures long-term battery health under all sorts of operating conditions as well as provides critical load control and system monitoring functions.

The two main types of charge controller

While charge controllers come in a vast range of prices, power ratings and features, they all fall into one of two basic categories: pulse-width modulation (PWM) and maximum power point tracking (MPPT).

PWM types are relatively simple, using a switch between the PV array and the battery. The switch is able to open and close rapidly, thus being able to pulse or “throttle back” the electricity coming from a solar panel in order to taper off the charge current as the batteries become full. Since PWM controllers operate with a switch only, the array voltage during operation is equal to the battery voltage. This means that you need to use nominal voltage solar panels with a PWM controller (36-cell panels for 12 V nominal and 72-cell panels for 24 V nominal).

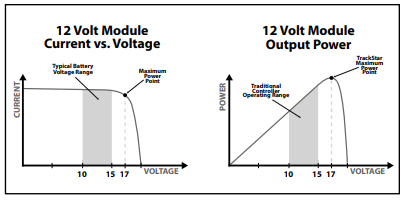

Even with a nominal voltage array, a PWM controller will operate below the maximum power voltage (Vmp). When it’s cold outside or when the battery voltage gets low, a PWM controller will operate well below Vmp and the max power (Pmp) rating of the solar array. To take full advantage of a PV array’s maximum power output, you need an MPPT controller.

MPPT controllers are comparatively more sophisticated. They can adjust (or track) the input voltage and current of the PV array to find the optimum operating voltage that will generate the most power at a given moment. Below are graphs of the current vs. voltage (IV) and current vs. power (IP) for a nominal voltage PV array. By continuously tracking and operating at Vmp, an MPPT controller will be able to generate more power than a PWM controller during bulk charging.

MPPT controllers can also be used with higher voltage PV arrays above nominal voltage. This makes it possible to use different solar PV panels which may cost less or be more optimal in size. For example, 60-cell cost less than 36-cell modules and are a more manageable size for mounting than larger 72-cell modules. Higher voltage arrays also allow for fewer strings in parallel resulting in fewer combiner box fuses, lower array current and less voltage drop, so smaller wires can be used, meaning that MPPT controllers can save money by reducing costly copper wiring, especially for longer array wire runs.

Note that while MPPT technology is more expensive, it’s not necessarily better. For a properly-sized system, MPPT and PWM controllers will both do a fine job of keeping the batteries charged. Choosing PWM or MPPT really depends on one’s application and location.

If there is not a long wire run and nominal voltage solar modules are being used, a PWM controller often is the best choice. The same is true in locations that may also have a lot of constant, dependable sunshine — in deserts or the tropics. In these locations, PWM controllers are the right tool for the job since some wasted solar electricity isn’t critical. Any advantage in using an MPPT controller may be minimal since the array voltage is lower in warm conditions. Another consideration is the size of the system. PWM controllers are often used in smaller, cost-sensitive systems where the added cost with MPPT is not worth it.

In places with variable sunshine, fluctuating temperatures and shading, in northern or southern latitudes with snowfall in winter, MPPT is by far more desirable since it can maximize output under challenging conditions. It all gets down to the right tool for the job.

Things to look for in a charge controller

It’s important to choose the right charge controller in terms of size and features. For remote systems, reliability and performance are very important considerations. Lower cost solar controllers are often not going to be the most reliable and may not meet vital charging requirements. Poor performance or reliability can end up costing many times over the cost of the solar controller in terms of replacement of the battery bank, site visits and loss of operating time.

Solar charge controllers must be designed to take a beating, since they deal with a lot of heat and have to manage it properly. Small charge controllers have the advantage of being fanless — they get rid of heat by simple passive cooling. By eliminating the fan they achieve three advantages:

- Higher reliability — Fans have moving parts, usually the only component with moving parts on a charge controller. Eliminate the fan and you eliminate one of the most common points of failure.

- Longer life — Fans pull in dirt, dust and even insects, which can clog the charge controller’s insides and shorten its life.

- Greater efficiency — Fans require electricity to run, and that electricity comes from the solar electricity flowing from the panels. Fans are a “parasitic load” in the system, diverting and consuming power that could be used elsewhere.

Some larger controllers (including all Morningstar controllers) also use passive cooling with no fans, incorporating very advanced thermal mechanical design and software. They are preferred in remote, mission-critical installations where maintenance is infrequent and replacements are difficult.

Smaller charge controllers will often only have preset charge settings. If the battery charging requirements are not sufficiently met with these presets, a controller with more settings options can be selected. Custom settings can be simple adjustments to voltage set points, particular applications or environments. For example, a system which does not cycle much can be set up with reduced daily absorption time, which is the amount of time before it puts the battery into float.

Select Morningstar controllers also have custom settings options for daily lighting on/off control. This type of control automatically adjusts the lighting on/off control independent of the time of the year so lights will come on when it gets dark in the evening and/or in the morning before it gets light.

Whatever your application, location or budget, the most important step in controlling a solar + storage investment is spending time and care selecting the right charge controller. Morningstar has sold over 4 million charge controllers in 100 countries, over the past quarter-century — and we’ve yet to have a single customer tell us they wished they skimped on this critical system component.

Douglas Grubbs is an applications engineer at Morningstar Corporation, providing product applications and technical sales support as well as ensuring technical and electrical code compliance. He has more than 11 years of experience in the PV industry. Prior to joining Morningstar, Douglas designed grid-tied solar PV systems for integrators in the Northeast and was also responsible for solar PV research and development at Bucks County Community College, teaching entry-level courses. His past experience includes nearly a decade with the Federal Communications Commission (FCC) as Electronics Engineer. Douglas holds a BSEE from University of Maryland and was formerly a NABCEP-Certified Solar PV installer.

Douglas Grubbs is an applications engineer at Morningstar Corporation, providing product applications and technical sales support as well as ensuring technical and electrical code compliance. He has more than 11 years of experience in the PV industry. Prior to joining Morningstar, Douglas designed grid-tied solar PV systems for integrators in the Northeast and was also responsible for solar PV research and development at Bucks County Community College, teaching entry-level courses. His past experience includes nearly a decade with the Federal Communications Commission (FCC) as Electronics Engineer. Douglas holds a BSEE from University of Maryland and was formerly a NABCEP-Certified Solar PV installer.

Disclaimer: We cannot provide advice on your specific project needs. Please reach out to charge controller manufacturers for more information, or assist each other in our comment section, below.

Good morning , i installed 1200watts solar panels of 200watts each in six (6) panels of 24 volt. The solar panel controller is 45 amps 24volts and installed 2 piece 12 volys batteris its tall tubular batteries , on 1500 watts inverter but, the issue its that not charging up to the expectation

I have no way of knowing your skill level, but this is common with solar arrays designed and assembled by people who dont know the limitations of solar panels and controllers….

1200w @ 24v would equate to 50amps….. but to help figure out where its failing you, you need to state what your expectations of the system are…. because if you misunderstand the system limitations, your expectations may be too high….

what part of the globe are you located?… or more specifically, what is the latitude where you are located?…. and how have you determined that the array is not meeting your expectations?

because of the wattage you have available from the panels, and only using 2 batteries (which we dont know how many amp hrs they are rated at), it may be producing more power than the batteries can uptake (which will be only about 25% of their amp rating) and again, as we dont know the capacity of the batteries, it may be possible that the 1500w inverter cannot pull enough power from the batteries quick enough to supply your needs……

so, there is some important information missing from your statement that needs to be known before anyone can help you understand if there is actually a problem…..

around the 45th parallel north, its recommended to expect no more than 50% of what the array is “rated” at….. on clear sunny days, it may be closer to 95% of their rated capacity, and on rainy days it may not produce any power at all…. but with a large array like you have, if the panels are wired in series, you would have very few days in a year that it would not produce any power at all…. installing a system with the expectation of it only producing 50% of what the tag on the panels say, you should be happy…… but if you are expecting 50amps from what you have, every hour of every day, you will be disappointed….

and the inverter cannot produce any more power than it can get from the battery bank….

Great article, Thanks for the detailed analysis of solar charge controllers. This article is very helpful for choosing the best one.

I have a problem with my system,I have a 120watts solar panel fitted with the 100amps battery and a 10 amps controller.I fitted 3 20watts dc security lights with a dc photocell sensor,an left for 2weeks.I found that the battery had spoiled with an output of maximum of 9v..what could be the problem ..please advise

Hi, I have the following:

-Small Solar Inventer

-12V Battery

-80W Solar Panel

-30A Solar Charge Controller

So I have a problem, my battery doesn’t get full or not charging and it is still new.

I can’t even charge my phone for 15 minutes. Please help.

I have a 315w, 30v panel. I have 2 6v batteries and a 1500w converter. What kind of charge controller do i need?

I wrote on a fuelless generator, no fuel and no solar panels, it has a very long life span and it’s working very fine.

I have an enclosed trailer that has two 12 volt batteries running in parallel. I have them wired to a 2000watt inverter. I run some led lights and an AC unit in the summer. Maybe a TV also. Only use it once a week for probably 8 hours. What do I do?

Hello everyone

I have a 3*150 watts and 220amps luminous battery, I want to connect it pallarel what amps of solar controller charger should I buy

Is there such a charge controller that can manage a backup generator? When battery level is low (due to insufficient charge from the Solar panels), the charge controller can automatically start the generator to charge the battery?

Hi Mike , maybe you could try our hybrid inverter-charger , which can work with battery and without battery (charging with generator) automatically

Can I use solar panel, charger and battery without inverter

Yes. Your only on DC loads matched to your battery voltage

Sir I want to charge battery 48v with 30 amp.what sort of solar charge controller should be select .charger controlling should be adjusting please guide us

Good day.

Badly need your advice.

I am planning a small system. Most of the equipments I have are salvaged or donation from a scrap company.

Currently I have the following:

– 1 x 255W Solar Panel

– 1 x 100W Solar Panel

– 3 x 30W Solar Panel

– 1 x 600W Pure Sine Inverter

– 1 x 12V 100Ah VRLA Battery

Installation consideration:

– roof is already facing South and had a good sunlight without obstruction from 9AM to 4pm

– distance from solar panel to battery is about 10ft

– i’m from the Philippines

My question are the following:

– should i separate the system so it’ll charge the battery separately?

– what controller should i use for a low cost system like this?

– what safety breakers should i use?

– if you guys have a wiring diagram that you can provide, i will really appreciate it.

Thank you.

You need a separate charge controller for every type of panels, i.e. 3. connect the 3 30 W panels in series if you have no shading issues, otherwise in parallel.

i have 12 v 7 AH UPS battery and i can charge it using UPS current itself . but when i use it for LED light directly connected to the battery i need a discharge controller to stop when the battery is drained . how to achieve this , Please help me .

hi going to do off grid system ,got 4 ,245 w panels,to put on my 2 garages just lights and small heating system i put in whitch run off an 3kw immersion heater and 3 rads,what size batteries do i need,and would a all in one mmpt charge controller be ok and what size do i need,only a garage in my garden and got grid power in it,any info would be great ,thanks

have 200w panel to charge 2x12volt batteries in line. would i need 30 amp or 60 amp controler

You would only need a 30. But if you plan to expand with more panels in the future it’s better to buy a bigger controller and a pv cable box to manage all the panels

Why has no one answered the questions?

How many amps of MPPT solar charge controller to charge a 12volt 50amps battery energizing 155 watts of appliances incl solar panels how many watts needed? Thanks!

I have 10 – 230watt panels ,open circuit voltage 37volts, short circuit current 8.4 amps

12 – 6v 250ah batteries (24v system)

4024 Inverter

30 yard cable run from panel rack to controller

What is the most efficient configuration and size controller I can use.

I have been doing the calculations and I personally think you need to add an extra battery(12V) to make a total of 3 batteries connected in series. That would rack up you total battery voltage to 36volts.

About your solar panels, connect five(5) of them in series and then do the same for the remaining 5 but separately. In so doing, you would have 2 different series connections. Now connect this two in parallel. The reason is that, your 5 panels in series would amount to a voltage of 185volts which is good.

If my calculations are right, I firmly believe you should go for a 190 | 70 MPPT charge controller or a higher on. Do not go for something less than the quoted figure I have indicated else you run a risk of damage or even causing injuries.

Greeting ,

I am researching controllers that can handle (2) 350 watt solar panels , seeking your advice ?

Thanks for your time & shared information .

George

Hello,

Please at what voltage would my charge controller stop sending current to my battery for charging.

Am using 30A PWM charge controller, 150AH lead acid sealed battery, 2000W inverter, three pieces of 150W solar panel I.e 450W altogether.

Thanks in anticipation for your response.

You divide the wattage amount of your solar panel by the voltage amount of your battery to get the precise amount of charge controller in ampere that is sufficient for your battery.

E.g if you have a 12volts battery and a 200watts solar panel. That will be 200watts divides by 12volts is equal to 16.66 amps of charge controller needed. That means you need not less than 16:66amps of a charge controller needed. You can increase the amount of charge controller in amps if you plan to increase the Solar panel wattage in future.

Good afternoon.

My Question is a bit distant from charge controllers.

I would like to find out why there is so little mention made of 72 volt systems on P V side and battery pack configurations.

Do 72 v pose a threat or do the market consider it dangerous. personally I think it is a better base to work from to invert to 220 v.

Thanks for the platform.

You can use a 72 volts of a solar panel, if you have the accurate amount of charge controller needed to control the voltage directed towards the battery.

Hi I live in the south of England I’m building my system more for interest and pleasure I have 12x320w 12v panels i want to install 4 panels in series ie 48v for the morning sun and 2 strings of 48v for the rest of the day .

I also have 8x100amp gel batteries I’m looking to run a a off grid system as I have a main grid isolator to later when money is available to link in a on grid inverter to get the Seg playback as a all in one hybird inverter is around £1500. What do you recommend

Kevin

Hi Kevin, I’ll recommend you arrange your panels in two strings of 6. (6*12=72volts). Your battery is 12v and 8 of that is 96v(connected in series), your total wattage would become 12*320 = 3840watts. Your current would be 40(3840/96)

Charge controller of choice would be 90 | 60. Perfect for an of grid installation

“Note that while MPPT technology is more expensive, it’s not necessarily better. For a properly-sized system, MPPT and PWM controllers will both do a fine job of keeping the batteries charged. Choosing PWM or MPPT really depends on one’s application and location.”

I have put in some very simple telemetry monitoring stations that are solar PV powered. With a 100 to 150 watt solar PV panel, one can use a simple blocking diode from the panel, to pass solar PV power to the battery. This is interrupted by a high current relay to the battery and power buss to the telemetry. A simple program that uses one analog input to a PLC as a voltage monitor, allows the battery to fully charge from the solar panel and then allows a charge just above the battery charge point. So, say a regular battery charger would allow the battery to fully charge up to 13.6 volts. In this instance the battery was allowed to charge up to 14.25 volts, then shut off. The battery would dissipate this surface charge and when the voltage drops to 13.25 volts, the relay actually drops out allowing the connection between solar PV panel and battery. In that way the battery is kept (full) all day long and is allowed to draw down the battery at night. The telemetry was not that big of a draw on the typical 100Ah deep cycle battery, but these AGM lead/acid batteries were lasting 5 to 7 years in the field without having to be replaced.

With the lithium ion chemistry becoming popular, the MPPT with three point charging would be the most efficient use of the power coming from the solar panels. Lithium chemistry seems happy to fast charge from the lower end of say 30% charge to maybe 60% charge, then stepping down the amount of current and focusing on the voltage of the battery, then stepping down again to ‘float’ the charging voltage to finish off the charge cycle.