There’s an access problem within the solar industry. We’ve reported on it many times, when racial and income disparity prevents the widespread adoption of solar power. As the median income of solar owners slowly creeps down, there is still an expanse of low- to middle-income households and renters left out of the conversation. One nonprofit thinks it has a solution: locally made solar panels installed (for free) on these left-behind households. Not only will more solar be installed, but local economies will flourish through increased employment opportunities and an influx of extra spending cash from utility bill savings.

The Locally Grown Power (LGP) business model was invented by Kent Kernahan, a “serial entrepreneur” who owns many patents within power conversion industries and had worked at a startup in the early 2010s involved with solar microinverter architecture and microelectronics. He set out to answer the question of how to create sustainable middle-class jobs, and his experience in the solar industry set an ideal path forward.

“I had been through a series of startups and there was a revelation that happened to me in 2011. Everything I’ve ever done is in production in Asia. Is this the right thing to do?” Kernahan asked. “Our model [in the United States] is to divorce the idea of where an invention is going to be capitalized and manufactured from where it’s created. As a consequence, any new technology that’s invented gets financed and then immediately built overseas. We’re undermining our own economy with our innovation.”

If Kernahan could develop an improved solar technology and then produce and install it in a more confined footprint, the local economy would benefit significantly. He determined that a community nonprofit solar manufacturing and installation program would increase jobs, keep dollars local and solve some issues of environmental justice. LGP would develop plans for communities to set up solar panel factories and train installers to equip local low- to middle-income households with solar systems.

The nonprofit idea set a good foundation, and Kernahan sought a new way to manufacture improved solar panels that would be simple for these communities to produce. He took his patents and entrepreneurial skills, formed IdealPV and found a problem worth solving — hotspots on solar panels.

Fool-proof solar panels

Kernahan and IdealPV invented a way to eliminate reverse conduction in solar panels, or when negative voltage from shading, soiling or other issues causes the current to reverse its flow across a solar cell, which can result in early failure through hotspots. By preventing the electron flow from reversing itself, IdealPV’s technology can allow panels to be installed in less-than-ideal applications without additional electronics. Panels installed in partial shading would no longer require microinverters or power optimizers to ensure consistent power flow.

“You solve this one problem [of hotspots] and then a lot of the things we do to solar panels to make them not be immediately destroyed by hotspot conditions no longer have to be worried about,” Kernahan said.

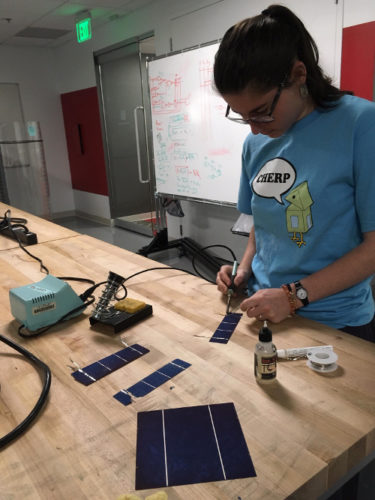

IdealPV panels are simpler to build because they use one row of cells connected in a serpentine-like series, which improves output and requires less wiring. The panels are easier to assemble — perfect for a nonprofit setting.

Prototypes of the IdealPV module have been tested at Harvey Mudd College and rated at nearly 270 W in the same footprint as a traditional 60-cell panel. Through the LGP business plan, IdealPV will license its solar panel design to qualified nonprofits.

Pilot program

Now with a technology to license, LGP needed a nonprofit organization to take that first plunge into the concept. After much searching, Kernahan found the Community Home Energy Retrofit Project (CHERP), a volunteer nonprofit organization in Claremont, California, that was created to eliminate the barriers to meeting national and local energy efficiency goals. Devon Hartman, CHERP’s president and executive director, founded the group in 2010 to assist with retrofitting buildings to become more energy-efficient, working as a consultant throughout the state to educate community organizations on “building science” and connecting them with the resources to get retrofits accomplished. After meeting Kernahan in 2015, Hartman realized Locally Grown Power could be CHERP’s capstone initiative.

“We can teach communities to retrofit their buildings but then also make their own solar panels to do the producing side, thereby accomplishing a comprehensive approach in greenhouse gases,” Hartman said. “We’ve got a comprehensive approach to retrofitting the building and then providing the solar and stimulating the local economy and addressing the low-income environmental injustice issues all at the same time.”

LGP’s pilot program was established to serve Claremont and nearby Pomona. CHERP is the local nonprofit behind the Claremont-Pomona Locally Grown Power chapter, and Hartman serves as Claremont-Pomona LGP’s CEO while Kernahan participates on the chapter’s executive board.

Harvey Mudd and Pitzer students (L-R: Nate Smith, Giulia Castleberg, Jacquelyn Aguilera, Christopher McElroy, Priscilla Chu) preparing how the IdealPV solar panels will be assembled.

Each LGP outfit is given the freedom to take different paths in executing the mission of sustaining middle-class jobs in the community. One nonprofit might have an underemployed disabled population that works well in the manufacturing location. It might place less focus on the installation side of the business. Another nonprofit might have individuals re-entering communities from prisons who are more adept to construction work. That one might make the manufacturing plant more automated while beefing up installation jobs. Claremont-Pomona LGP set off somewhere in the middle — creating 200+ jobs from manufacturing and installation with a goal of outfitting 6,000 low- to middle-income households with 16-panel (4.3-kW) solar arrays.

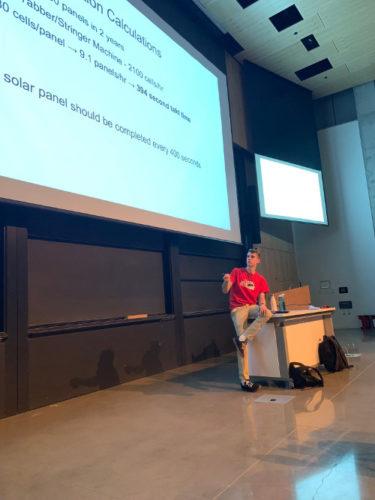

With a local mission established, Claremont-Pomona LGP reached out to solar experts and engineers at Harvey Mudd College for assistance on how to build a solar panel facility. Claremont-Pomona LGP has secured a site location, formerly a welding training facility with the Pomona Unified School District. Harvey Mudd students estimate the facility’s output at 50,000 panels per year, which is based on outfitting 3,000 homes (in year 1) with 16 solar panels. One panel should be produced every 6.7 minutes, based on a three-shift schedule. At 270 W apiece, Claremont-Pomona LGP’s annual production capacity should hover around 13.5 MW.

When considering solar panel plants with 50-times more annual capacity than Claremont-Pomona LGP’s 13.5 MW employ far fewer than the group’s aim of over 200 workers, one has to remember profits and output are not the goal of this facility — jobs are.

“It becomes [more] important that you create jobs for disadvantaged individuals than necessarily have the most automated factory you could possibly have,” Kernahan said. “Those people are in that community, and they’re a resource that’s being underutilized. For the nonprofit, this is seen as part of the mission.”

Initial concepts for the manufacturing plant call for three shifts of around 25 workers, while it’s estimated over 100 installation jobs can be supported. Claremont-Pomona LGP aims to have UL approval on the factory and the panels by the end of 2019 with full operation by spring 2020.

Economic impacts

The foundational basis of a nonprofit organization means that Claremont-Pomona LGP has to find money to pay for employment, training and the “free” installations it will be providing 6,000 local households.

“We have a whole workforce development team of professionals who are already helping us secure grants for training. We’ve already lined up about $700,000 worth of training grants,” Hartman said. “We’re going to be training and putting to work at-risk youth, veterans, out-of-work adults [and otherwise] challenged people.”

The group also caught a lucky break in June 2019 when a $2.1 million grant to Claremont-Pomona LGP was included in the 2019-2020 California state budget. That money will go directly to the development of the manufacturing facility. Assemblymember Chris Holden (whose district includes Claremont) helped secure this significant funding in the state budget.

“The California Legislature has set ambitious climate policies and I am 100% committed to furthering our leadership role in combating climate change, but we need all Californians to be able to be part of greener energy solutions,” Holden said. “The Locally Grown Power nonprofit model gives the opportunity for more Californians to have a seat at the table and be able to support our existing legislative priorities.

“I will follow the construction of the manufacturing facility and look forward to realizing the promise of Locally Grown Power in cities throughout the State of California that empower all Californians to play a part in clean energy solutions,” he continued.

Additional grants from environmentally conscious California are also helping. The state uses its “CalEnviroScreen 3.0” report to map census tracts by how much pollution they’re subjected to. Senate bill 535 directs 25% of cap-and-trade dollars be spent in these communities to reduce greenhouse gas emissions. Hartman said in total, that’s $2 billion of earmarked dollars required to be spent in disadvantaged communities. While Claremont doesn’t have a high mark for pollution, nearby Pomona has one of the higher scores in the Los Angeles area. And there are plenty more communities that need help, have the allotted dollars and could build off the LGP business plan.

With the guarantee of comped solar systems and reduced electricity bills, chosen households will find themselves with extra spending cash, and LGP officials believe that will be spent in the community, further improving the economy.

“Not only are we helping to achieve our very ambitious state greenhouse gas goals, but we’re also freeing up disposable personal income at the lowest household income level,” Hartman said. “A solar panel on a high-income household, that $90 a month saved would tend to get saved or invested and would most likely never hit the local economy. But if you save $90 a month for lowest-income-level households, that money tends to get spent immediately in the local economy on food, gas, clothing, medical supplies, school supplies.”

By outfitting 6,000 low-income households with solar, Hartman estimates that the surplus $90/month in utility savings will divert $6.5 million a year back into the local economy. Considering the increased local and state sales taxes that come with that, the program should easily pay for itself in fewer than five years.

While the concept seems fool-proof, Kernahan acknowledges it will be tough getting this first attempt at the LGP nonprofit model accepted in the industry. But bringing solar manufacturing and installation to a more localized level could be the first step to a major shift in the United States.

“This idea of building community wealth — you really want to produce your products in the markets where they’re going to be used if you want to generate the maximum wealth for your communities,” Kernahan said. “I think we’re on the right edge of where industrialization is going. I think the ultimate trend for manufacturing is going to be distributed manufacturing close to the point of consumption. This has never been tried anywhere else in the world, and now we have a front-row seat to see how this cutting-edge approach to distributed manufacturing can work.”

Is there an application process in place for other micro manufacturing facilities?

I work for a safe-energy non-profit in San Francisco, Abalone Alliance Safe Energy Clearinghouse. Since 1982 our office has been located in the Redstone Labor Temple, formerly owned by SF Labor Council and now a community center housing nonprofit organizations, artists and theater spaces. The building is zoned for light manufacturing and our location in a working class neighborhood gives access to lots of potential people who could be helped, one of the building’s non-profits serves the homeless population.

Please let m know what would have to happen to pursue this further.

If you reach out to LGP directly, they may be able to answer your questions: https://www.cherplgp.org/

I’m so impressed and very excited about the potential on so many fronts: jobs, education, clean energy, local economic stimulus, and so much more

I’m impressed by your hard work and I hope this opportunity could reached out to clinics and schools in my country Liberia west Africa. With such opportunity many lives could be save from delivery and adult illiteracy program for women and girls.

Tom: what of the technology and execution do you feel is “suspect?” The technology is patented in the US (pending in the EPO) and was verified by the physics department of Harvey Mudd College. HMC found that in real world conditions the IdealPV panels produced 59% greater power. They also verified that hot spots cannot be created, and in fact a partially shaded cell would be a little bit cooler than the surrounding cells (less insolation). As for execution, the factory facility is being updated at this time.

Glad to see the dedication of the guys for installing pv module free of cost. In hilly areas of Bangladesh, our government is providing solar home system and solar community systems totally free to the poor hilly tribes. I am glad to get the job done from scratch to end , and enjoy the innocent smiles of the beneficiaries. There are still many spaces here to support poor people with such kinda project.

The concept of bringing solar PV to all people in the community is a good one. The challenge will lie with the technology and the manufacturing execution. Both of these appear highly suspect.

I am impressed by the concept. It is incredibly unselfish and largely beneficial to our planet and the life on it. In this part of the world (Africa), I understand what such a wonderful non-profit entrepreneural Innovation could do for the low to middle-income house holds. 90% and above of the population will benefit.

I wish to get updates on the progress of this blessed venture.

Such an inspiring and hopeful story! Onward!