By Bob Wood, chief operating officer and chief technology officer, Trimark Associates

By Bob Wood, chief operating officer and chief technology officer, Trimark Associates

Technology exists to improve our lives. For those in the energy industry, SCADA system technology helps to operate solar sites. An acronym for Supervisory Control and Data Acquisition, SCADA is a system that links together numerous hardware and software components of a site in order to easily monitor, control and analyze performance. Those components continue to expand, helping solar operators analyze all relevant solar project data in one place.

SCADA: The basics

All SCADA systems monitor data from a plethora of devices, including meters, inverters, weather stations, trackers, DC strings and substation equipment. At a basic level, these systems provide actionable information to determine whether or not solar plant equipment is performing as expected, identifying offline and malfunctioning equipment. System operators and performance engineers can analyze the SCADA data and determine when to deploy technicians to resolve any issues.

When plant owners manage multiple sites, it’s critical to employ more automated methods of identifying and addressing performance issues. Also, with tight operating margins, they need an economical solution to analyze and investigate root causes of issues. SCADA addresses these necessities, simplifying how owners run their sites.

As analytics, widespread services integration and numerous other technologies continue to advance, leveraging SCADA to improve a site’s operations without increasing costs is as simple as ever.

Details in the data

Traditional SCADA systems constantly monitor equipment at a site and record sampled data to a local historian. The real-time data is visually represented on operator screens and is used to evaluate alarm conditions. Most systems provide a summary of the collected data to show trends and identify anomalies, as well as showcase design queries and reports that summarize the data for operational maintenance and management. The data is exported from the historian regularly for further analysis in other data management systems, where it is augmented with rate schedule details, maintenance management data, modeled data, weather data and more.

Traditional SCADA systems constantly monitor equipment at a site and record sampled data to a local historian. The real-time data is visually represented on operator screens and is used to evaluate alarm conditions. Most systems provide a summary of the collected data to show trends and identify anomalies, as well as showcase design queries and reports that summarize the data for operational maintenance and management. The data is exported from the historian regularly for further analysis in other data management systems, where it is augmented with rate schedule details, maintenance management data, modeled data, weather data and more.

Since a SCADA system already stores plant operational data, it makes sense to incorporate advanced analytics and performance management functionality into the same SCADA system rather than add external systems. This reduces overall operation complexities and costs. On top of this, collecting data in real time allows for performance issues at plants to be more readily addressed.

Effortless management

To determine a baseline of how a site should perform, an engineering analysis is typically conducted before and after construction. This information, which is used to calculate actual and projected performance, is part of a plant’s overall financial management reporting. SCADA systems should incorporate a plant’s performance expectations and then analyze and compare that data to actual performance. Reports should show the site’s performance relative to expectations.

Taking this further, an effective SCADA system should incorporate the following functions.

- Weather forecasts: By integrating weather forecast service support, along with expected performance, the SCADA system can provide accurate energy forecasts, providing insight into data and sensor calibration.

- Device-level analysis: When performance is analyzed at the individual device level, such as individual inverter capacity, string counts and installed solar panel specifications, a SCADA system can alert operators and maintenance technicians of device performance issues and the level of impact for quick analysis.

- Tracker angles: Adding calculated tracker angles into the SCADA system identifies when trackers are not tracking to the optimal angles, resulting in decreased energy production.

- Lost energy analysis: Lost energy, a measure of the amount of energy that would have been produced if all devices were functioning optimally, provides historical details to analyze underperforming devices.

- Rate schedules: Including Rate Schedule Awareness enables the SCADA system to know the value of the energy produced by the plant or the value of the energy not produced. This information is used to evaluate a plant’s financial performance.

With comprehensive, real-time analysis, plant owners and operators don’t need to constantly and actively look for issues at a plant. The SCADA system can provide performance-based alarms to alert operators when a site, or individual devices within that site, are not performing optimally. When managing multiple sites, resource owners and operators greatly benefit from the automated alerts from advanced SCADA systems.

An integrated system

Introducing integration to a utility energy management system enables the utility to monitor critical plant functions in real-time and to incorporate Automated Generation Control (AGC) to control the plant output. With advanced SCADA systems and additional integration capabilities, automation and control can be taken a step further.

- Satellite weather/forecasting: Integrating one or multiple weather services to augment plant information with area weather observations and forecasts helps to estimate energy production from the plant.

- Meter settlement: Integrating meter reading systems ensures accuracy in settlements.

- Billing systems: With complex rate schedules, the billing process can be tedious. Having to export the SCADA system data into a separate, complex spreadsheet and then enter that data into an accounting system is time-consuming. However, when integrating billing into a SCADA system, this process can be automated, creating invoices without manual manipulation.

- Document management: Rather than storing engineering, contract, compliance and procedure documents in a document management system, the system can be integrated into the SCADA system. Documents can be easily accessed from the SCADA system for ease of organization and control.

Perfection through analytics

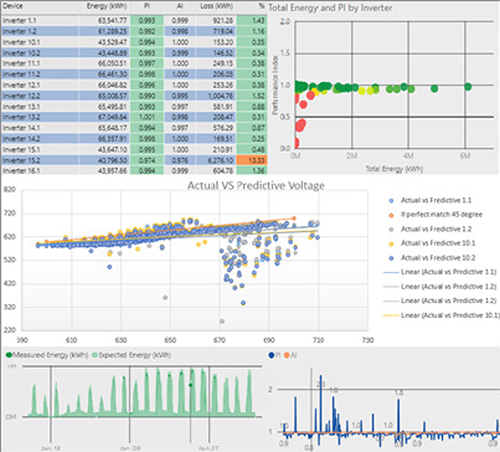

Applying analytics to a solar facility provides valuable insight into the project’s performance. Presenting this data visually using graphs and reports on intuitive dashboards helps to maximize performance and outline information. For example, performance across an entire fleet can be reviewed and compared, with fleet information sorted by type and equipment.

While this type of analysis has traditionally been done on separate systems, advanced analytics are being increasingly integrated into SCADA platforms for direct data management. Cost-effectiveness aside, the ability to organize both historical and real-time data in a variety of ways — by type, model, performance, etc. — enables solar project operators to immediately adapt to recognizable trends, thereby optimizing their generation and maximizing revenue.

A lasting impact

Technology is ever-evolving and SCADA systems are no exception. Already a flexible system for collecting and managing generation data from sites, SCADA systems have broadened — rather, transformed — into an all-in-one business management system that supports just about every aspect of a plant. The innovative, comprehensive functionality of this technology cannot be understated, nor can the excitement it brings to the energy industry. Whatever the next breakthrough in SCADA may be, there is no doubt it will make the lives of site operators everywhere that much easier.

Bob Wood oversees and manages day-to-day operations at Trimark Associates, including systems integration and engineering, software development, fabrication/production, revenue metering, and data management. Bob has served in executive operations and technology positions in the solar development, banking, law and technology sectors over his career. His extensive experience in operations management and strategy, information technology, and process improvements has given him a unique perspective on the application of information technology to attain an operational advantage.

Bob Wood oversees and manages day-to-day operations at Trimark Associates, including systems integration and engineering, software development, fabrication/production, revenue metering, and data management. Bob has served in executive operations and technology positions in the solar development, banking, law and technology sectors over his career. His extensive experience in operations management and strategy, information technology, and process improvements has given him a unique perspective on the application of information technology to attain an operational advantage.

What are the best SCADA vendors are out there?

“All SCADA systems monitor data from a plethora of devices, including meters, inverters, weather stations, trackers, DC strings and substation equipment. At a basic level, these systems provide actionable information to determine whether or not solar plant equipment is performing as expected, identifying offline and malfunctioning equipment. System operators and performance engineers can analyze the SCADA data and determine when to deploy technicians to resolve any issues.”

My experience with SCADA, for 33 years is your SCADA needs to be graphics and point rich, to make on the fly decisions when alarms indicate a problem at a site. Your control operators are the eyes and ears of the system, their attentiveness can make or break the operation. By and large engineers are more interested in nice compact tables and graphs to use on the next project to go online within the system. When regulatory compliance is the issue, a properly appointed SCADA system can save the company money even (if) a regulatory violation occurs. When one goes from operation malfunction to regulatory violation, the SCADA can still isolate the violation and define the amount of time such a violation did occur. This too can save money in fines from regulatory agencies. Run time predictable data like domestic pump hours of use, can generate maintenance work orders for so many hours of pump run and can save thousands of dollars in large pump stations from emergency down times. Why not solar PV evaluation and operation of plants. Using weather modeling and prediction algorithms can also help in determining when and how to store, curtail or pass through energy to the grid as needed. The problem I see is the IoT. IF you can program it, you can hack it. IF you can hack it, you can disrupt it or control it to failure. These are real threats, with dire consequences for those who easily want the nifty technology for ‘their’ system and believe the IoT SCADA salesman naively.