When it comes to estimating the amount of energy a solar design will produce for a customer, accuracy is key. It is clear that overestimating a customer’s solar production is problematic because their utility bill savings will fall short of what is promised. But underestimating can also be detrimental because production in excess of the customer’s annual consumption is typically only compensated at a wholesale rate. Therefore, the customer ends up with too big a system for their needs—and a prolonged payback period.

Fortunately, there are a number of software programs available to help estimate the energy production of a solar installation—but not all provide equivalent levels of accuracy. Understanding the factors that affect the accuracy of a performance simulation helps ensure that estimates align with what the installed system actually produces.

In today’s article, we explore three factors that significantly impact the accuracy of energy production estimates when shade is present.

1. Physical site characteristics that impact shading

One of the most important factors in accurately estimating energy production is precisely accounting for all of the physical features of the site that may shade the array. Anything from vents on the roof to nearby trees can have a shading impact. It’s essential that your preferred software models each element to arrive at an accurate production estimate.

In the case of Aurora’s software, a precise 3D model of the project site is used as a starting point. Aurora’s shading engine then calculates how each object will cast shadows during each hour of the year. This process takes into account the project location and local weather data to generate remote shading assessments that have been found by NREL to be statistically equivalent to onsite shade measurements. Additional tools like computer vision and high-definition aerial imagery make it easier for solar designers to ensure they have not overlooked any characteristics of the project site, from vents and pipes to skylights, chimneys and neighboring buildings.

For sites with many obstructions like this commercial project on a shipping warehouse, modeling vents, skylights and other roof features is essential to accurately simulating the PV system’s energy production.

This approach ensures that shading at the site is quantified accurately, which is a critical starting point. From there, however, there are a number of additional capabilities that simulation software should include to accurately model how shade will affect the energy production of a PV design.

2. Variations in stringing configuration

The stringing configuration of a design can have a significant impact on the amount of energy it will produce. This is because the configuration in which modules are connected impacts the way electricity flows through the system when shade is present. Not all programs for modeling solar energy production take into account variations in the way modules are strung.

A small amount of shade can have a disproportionate impact on the energy production of an array because a shaded module acts much like a clog in a pipe, reducing the flow of current of the entire string. The flow of electrical current through the string is limited to the level of current of the most shaded module, as illustrated in the figure below (except where microinverters, DC optimizers or bypass diodes mitigate this effect).

The current flowing through a string of solar modules can be thought of as similar to the flow of water through a pipe. Much like a clog reduces water flow, a shaded solar module reduces the flow of current through the string.

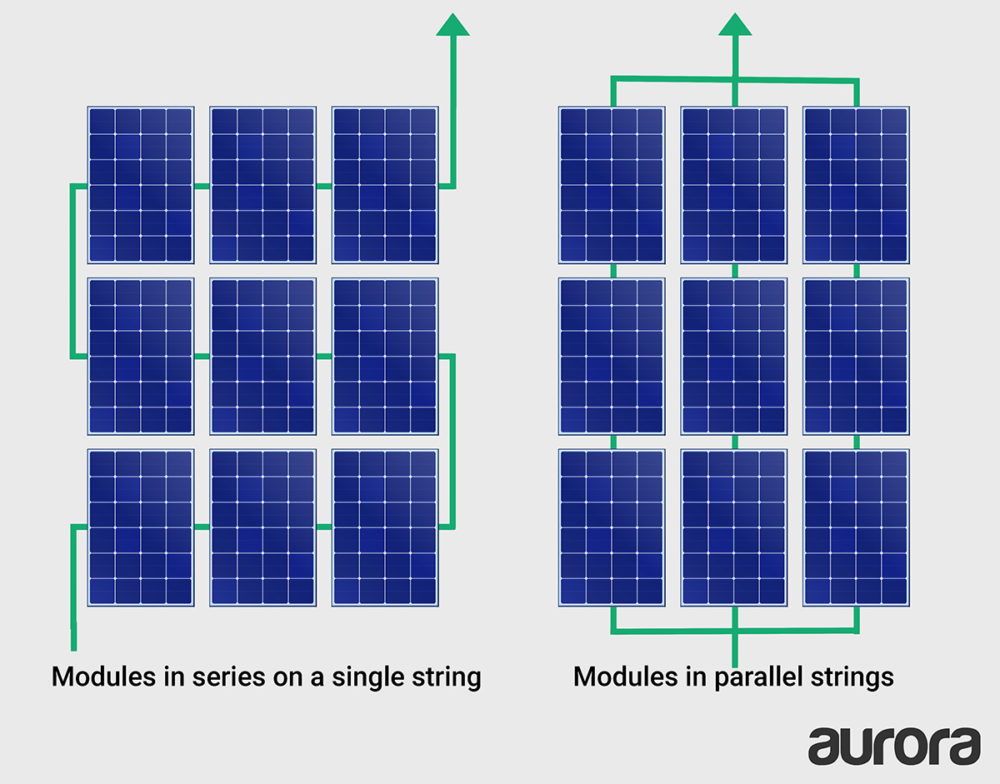

However, shaded modules in one string do not impact the power output of other, parallel strings (illustrated below). This can make it beneficial to group modules that will receive shade into separate strings. A software program that does not simulate energy production based on the specific stringing configuration used in a PV design, however, will fail to account for the performance benefits of such an approach.

An illustration of two stringing configurations for solar panels in an array: stringing in series or in parallel.

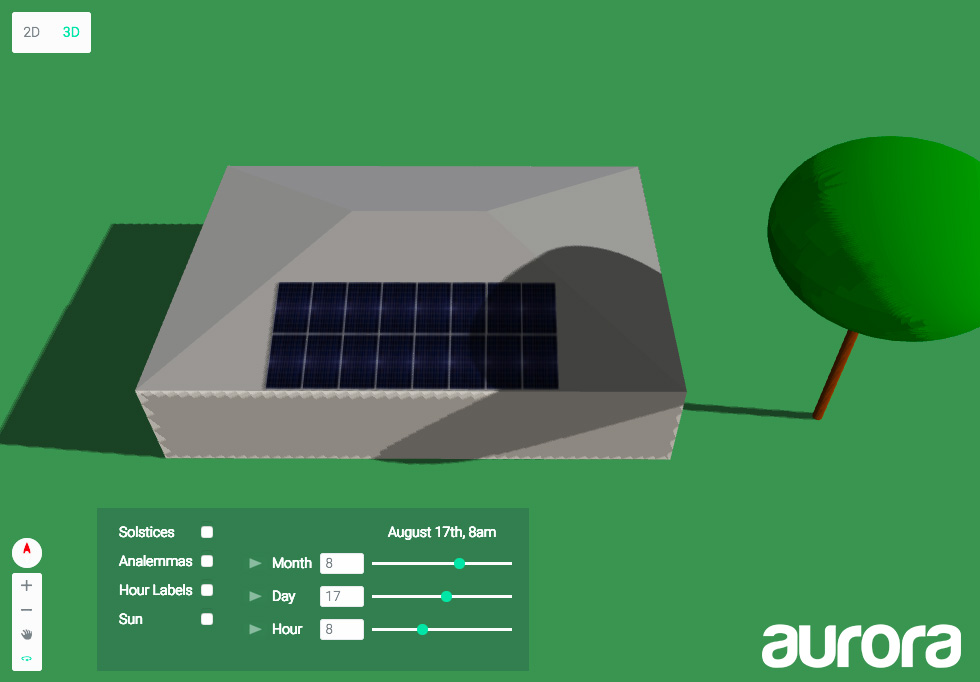

To explore this phenomenon, we conducted a case study of a 4.8-kW PV design on the south face of a roof, where a tree shades the eastern portion of the system in the early mornings (as shown below).

A 3D model of the project site simulated in this case study by Aurora Solar, where a tree casts shadows on the eastern portion of the system during the mornings. (The location of shadows at 8 a.m. on August 17 is shown; Aurora models the shading on a solar design at every hour of the year.)

In the first design, we strung the panels in series; in a second design, we separated the east and west panels into two groups on separate strings. Aurora’s simulation engine calculated the annual energy production of the second design configuration at 7,666 kWh compared to 7,495 kWh for the first, demonstrating a gain of 171 kWh annually from grouping shaded modules into separate strings. Over the 25-year system life, this translates to an additional 4,275 kWh for the customer—at no additional cost. For a larger system, the gains could be considerably more.

Two different stringing configurations modeled in the above case study. Separating the eastern group of panels, which receive more shade from a nearby tree, into a separate string (right) yields production gains of 4,275 kWh over the lifetime of the system compared to stringing all of the panels in series (left).

3. Electrical behavior at the cell string level

These effects of shade don’t just apply at the string level, they are also at play within each solar module at the cell string level. Just as a single shaded module can reduce the flow of electrical current through the rest of the string, a shaded cell within a module can reduce the flow of current through the rest of the cell string.

This problem has been significantly improved by the inclusion of several bypass diodes within modern solar panels. When only part of a solar module is shaded, bypass diodes make it possible to circumvent the shaded cell string, allowing the rest of the module to operate at maximum power. In the case of a module with three cell strings and three bypass diodes where only one cell string is shaded, bypassing the shaded cell string reduces the module’s power output by roughly a third rather than losing all of the power output from the module.

The simulation engines of many solar software programs are only capable of modeling energy production at a module level. However, simulation at a cell string level can have a significant impact on energy production estimates in cases where modules in the installation receive partial shade, such as in a tightly spaced commercial design that experiences inter-row shading (e.g., a row of modules partially shades the modules of the neighboring row).

Aerial views of designs featuring 3-ft (top) and 1.5-ft (bottom) row spacing at noon in mid-December. Adjacent rows do not cast shade on each other in the design with larger row spacing, while there is significant inter-row shading in the design with narrower row spacing. When inter-row shading is present, software that can simulate solar energy production at a submodule level is needed for true accuracy.

As demonstrated in another Aurora case study (shown above), this additional precision can alter estimated energy production by a few percentage points. While this may sound small, for larger systems a small change in energy production can translate into a significant dollar value. Aurora allows users to select whether to simulate energy production at the module-level or a submodule-level, enabling greater precision in designs where partial shade is a factor.

Submodule simulation is also necessary to accurately model the energy output of designs that include DC optimizers, some of which operate at the submodule level to reduce the impacts of shade and can offer substantial performance benefits.

Understanding factors that affect the accuracy of energy production estimates can help contractors choose the best solar modeling platform for the job and consistently deliver on promises to customers.

Interested in learning more? Watch the free webinar recording of “Designing for Performance: 3 Techniques to Boost Solar Installation Yield” now.

Tell Us What You Think!