Some big solar headlines of early October 2017 read that the world’s largest rooftop solar tracking system had reached completion. “World’s largest” seems impressive but could easily have been replaced with “world’s only.” Trackers don’t go on roofs; the wind would rip them off, right? And now there’s a 1-MW rooftop tracking system online in California? It seems crazy, but new technology shows otherwise.

Edisun Microgrids, a solar technology company born out of the incubator Idealab, has spent the last few years perfecting the rooftop solar tracker it calls PV Booster. More than 2,900 trackers attached to individual panels were used on the “world’s largest” project on a Chiquita cold storage building in Oxnard, California. The individual trackers are key to the project’s success, said Edisun Microgrids founder and CEO Bill Gross.

“All of the things you do to mount the [tracking] system in the ground—drilling holes or putting pylons in or ground screws—you can’t do on a rooftop. The roof isn’t strong enough to hold those forces of the wind on rows of trackers,” Gross said. “I thought maybe there was some way if we modularized it or broke it down into smaller elements, you could reduce the individual point loads from the wind to be small enough to actually make a tracker work.”

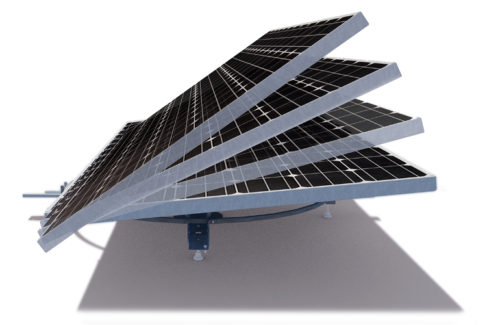

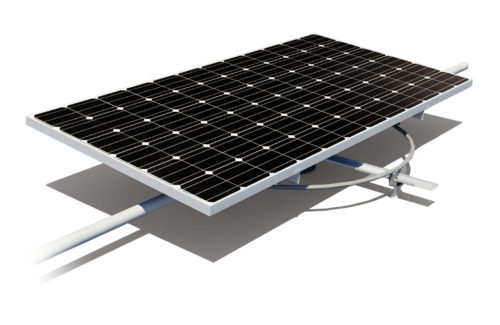

He was right. Trackers can operate on a flat rooftop if they’re held closer to the roofline. Traditional ground-mounted dual-axis trackers attach tables of panels on a pole many feet off the ground. A tall pole-mounted system couldn’t work on a roof; it couldn’t support the weight or wind loads. Reducing the PV Booster’s support to one single panel helped lessen weight, but a new pivoting/tracking solution was necessary.

“We came up with a new mechanism where the panel pivots from the front edge,” Gross said. “It’s a carousel design. As opposed to pivoting from the middle, we make a ring which is the diameter of the size of the panel. We pivot from the front edge and hinge it at the front edge so when the panel retracts, it goes down full flat. We are only a few inches off the roof in the stowed position as opposed to 6 ft off the roof in the stowed position [like traditional pole-mounted trackers]. That difference of a few inches versus 6 ft is the whole difference of surviving the wind load.”

“We came up with a new mechanism where the panel pivots from the front edge,” Gross said. “It’s a carousel design. As opposed to pivoting from the middle, we make a ring which is the diameter of the size of the panel. We pivot from the front edge and hinge it at the front edge so when the panel retracts, it goes down full flat. We are only a few inches off the roof in the stowed position as opposed to 6 ft off the roof in the stowed position [like traditional pole-mounted trackers]. That difference of a few inches versus 6 ft is the whole difference of surviving the wind load.”

Gross has experience with tracking systems. As part of his technology incubator Idealab, he developed a single-axis tracking system for ground-mount installations under the name RayTracker. The company worked primarily with First Solar and was eventually acquired by the EPC in 2011.

“We were trying to make a product that was simpler to install on the ground, where each row could be independent,” he said. “Since [the acquisition], First Solar has done about 1 GW of that tracker in their systems. I saw the market grow again like crazy for the ground-mount business—millions of dollars and gigawatts of installations. I was looking at the market, saying, ‘It’s taking off on the ground so much, why is no one doing it on the roof?'”

“We were trying to make a product that was simpler to install on the ground, where each row could be independent,” he said. “Since [the acquisition], First Solar has done about 1 GW of that tracker in their systems. I saw the market grow again like crazy for the ground-mount business—millions of dollars and gigawatts of installations. I was looking at the market, saying, ‘It’s taking off on the ground so much, why is no one doing it on the roof?'”

One reason might have been the economics. After Edisun Microgrids determined individual trackers would work best, the next challenge was how to make a system cost effective enough to support thousands of trackers on a roof. Gross said the dual-axis tracking helps and provides a 30% boost in power compared with fixed-tilt roofing systems. Also, increasing panel efficiency and power make a big difference. A 400-W panel will obviously produce more power than the 250-W models of a few years ago.

“We can cost 10% more with a 30% boost in power and still have 20% better economics,” Gross said.

The PV Booster also uses a perimeter drive system, moving the torque load from the center to the outside ring.

The PV Booster also uses a perimeter drive system, moving the torque load from the center to the outside ring.

“That extra reduction from the torque by driving from the perimeter means we can use a direct drive motor, getting rid of the gearbox,” Gross said. “Eliminating the gearbox eliminates the two most difficult things of a tracker—the expense and the reliability.”

Edisun Microgrids has 20 MW of PV Booster projects in the pipeline, and the company is actively looking for opportunities with solar installation companies used to large commercial rooftop installs.

“If they can install fixed-tilt racks, they can install our tracker,” Gross said. “It’s new technology, but we provide all the service and support to help them learn. We’re especially looking for people with customer relationships that can explain our technology to customers and expand our reach. We think long term. In one or two years, everybody will at least evaluate a tracking system for their commercial rooftop alongside a fixed tilt, because it makes so much economic sense.”

There is significant potential in the commercial rooftop market for solar. The Commercial Buildings Energy Consumption Survey (CBECS), administered by the U.S. Energy Information Administration (EIA), estimated there were 5.6 million commercial buildings in the United States in 2012, comprising 87 billion sq. ft. And buildings are expanding: The survey found a 21% increase in floorspace since 2003. With major tech companies (think Amazon, Google, Apple) building new headquarters and data centers at 1 million sq. ft or more, the market can only grow for rooftop solar opportunities—especially if trackers help the economics make more sense.

“We want to help show the world that tracking on rooftops is just as valuable as tracking on the ground,” Gross said. “I hope with the progress we make over the coming year with our pipeline, we will help convince people that if they’re going to put solar on a large commercial building, you should at least put tracking into consideration.”

space is not only the issue but for me , the selectricity board here only allows 6kw to be put through their system , so on the grounds of that the system must be efficient , as adding panals will go beyond the limit where you can broaden the morning and evening .

any one know of a feasable system for domestic

This article was written in January 2018. It is now 5 years later, yet I am still reading the same argument: it is cheaper to add panels than it is to install solar trackers. Granted, the cost of panels has steadily declined, but what about the corresponding cost of trackers? I recall reading articles from a decade ago that referred to trackers in the range of $2500 per panel and recent ones that had reduced the cost to $500-1000, depending on whether it was single- or dual-axis. One would think that the technology and the fabrication costs would have declined more than that. And given the federal incentives for residential solar installations, the critical mass would soon be obtained. Aside from individual cost, if the national energy policy is to generate as much electricity as possible, it would make sense for the government to prioritize smart articulating mounts and reduce clipping during the prime generating hours of the day.

The issue is that all of the technologies to make a tracker system (the timed/GPS/detector systems, frames, mounting hardware, and motors) are all long-since matured technologies used for a variety of functions, while PV is a rapidly improving technology not yet at maturity. Plus, the costs of materials keep going up for traditional technologically mature equipment, while never-ending refinements in PV production methods and economies of scale continue to cause their costs to plummet. And the economies of scale for the specific manufacture of PV trackers will never mature when just putting up more panels is so much cheaper.

They still have a market niche for squeezing more electricity from PV out of a given area of land/roof/whatever where you want as much solar production as possible within a given limited space footprint (like the roof of an apartment complex that has much less roof space per domicile than single-family homes). But a hydraulic boom or gear-driven electric motor haven’t gotten appreciably cheaper. Solar trackers are extremely simple and until someone comes up with some sort of magic bullet in an already-mature technology field, they won’t get appreciably cheaper.

Can this mount on the roof of a vehicle? Tracking would only function when the vehicle is not moving but seems a great application due to limited space.

It is simple

“Gross said the dual-axis tracking helps and provides a 30% boost in power compared with fixed-tilt roofing systems. Also, increasing panel efficiency and power make a big difference. A 400-W panel will obviously produce more power than the 250-W models of a few years ago.”

Now the question is, what is cheaper, a system with n panels with these trackers, or a system that has N time 1.3 panels. They both deliver the same number of wH’s a year. But which one is cheaper.

Depending on where you are I believe a flat roof without shadows on it, should just simple be filled with as many panels you can buy.

Only when little room is available a tracker can do some work

ok, you’re gaining panel efficiency, but reducing panel population by separating them to allow in-motion panels to clear one another… fine, i guess, where available mounting area isn’t at a premium … i’m wondering about a system where you’d have panels no-gap mounted as usual on roof, and have uni-directional motion- just elevation adjustment … it wouldn’t be quite as per-panel effective as doing both azimuth and elevation, but just an up/down tilt would get you substantial return, as well as be probably much simpler to mechanize

I know of a dual axis tracker that was on a pole, yet attached to a building with a large U bolt. Every time the tracker adjusted (every 15 minutes or so) the woman working in the adjacent interior office would hear/feel it. Perhaps on a warehouse this is not an issue, but I didn’t see vibration and/or noise mentioned.

Due to roof shape and vent ports my South facing roof has no panels, all are on the East and North facing (24º slope). My energy production during the late fall to spring is not good. These tracking panels could mean a huge difference in my energy production.

perhaps these mounts would be good for carport/free standing shade structures?? Looking for roof mount alternatives…

maintenance/service areas might dictate the ring tracking system. I will not allow roof mounts on my mission concrete tilled roof. I am looking at ground/pole mount arrays in multiples to produce 24kw daily.What is your suggestion??

I have 19 panels, 385 WH each. It is Late Feb 2022 in Surprise Az. Newly installed, Enphase IQ7+ microinverters. Full sun, I am getting 35 KWH per day and increasing as the sun gets higher. Panels are all mounted on the west facing roof. Fun to watch power generation on the Enlighten app.