By Judah Moseson, PE CEM, vice president of operations, Cooke Power Services

The balance of plant (BOP) is the most important link for delivering power produced by a solar farm to the marketplace. The BOP consists of the pad-mount transformer at the exit of the inverter through to the collection system and substation. The BOP also includes transmission lines, the roads and drainage.

While most O&M discussion focuses on components related to the PV panels and tracking systems, the BOP equipment also needs attention. It is wise to plan for best-in-class BOP inspection and maintenance procedures to maintain a highly functioning solar farm. The inspections outlined here represent essential activities that help ensure safe and profitable operation of a solar farm.

The challenge for solar-farm owners and operators is to recognize the need to budget for these procedures. Their costs represent less than 10% of the total O&M budget of a typical solar farm. To keep that link in power production up and running, this article focuses on how to inspect the medium-voltage (MV) equipment from the pad mount transformers, collection system, substation, and the high-voltage (HV) equipment in the substation.

Pad-mounted transformers

These transformers are required to take the inverter output and step it up to the MV of the collection system (typically 34.5 kV) for efficient transmission to the substation. These transformers have had a number of issues that have required an action plan for inspection and maintenance.

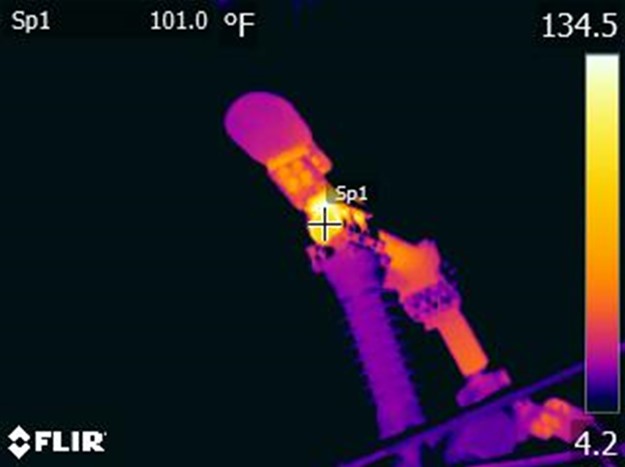

IR inspection is a non-evasive examination of the transformers online and under load. The accompanying image shows loose or damaged connections.

The results of the inspection are known immediately and a brief outage is typically all that is needed to correct the issue. Without an inspection, loose or damaged connections may eventually fail, causing damage to the transformer and posing a safety risk to personnel.

The IR image reveals three loose or damaged connections at a pad-mount transformer. The three connections are the three phase low voltage cabling connecting this transformer to the inverter output. Loose or damaged connections are responsible for the increase in heat. The good connections remain cooler.

Oil sampling of the transformers is a typical practice. Unfortunately, the solar industry has been slow to react to the results of this testing. A preferred action plan should be to identify the root cause of the poor test results and take corrective actions such as internal repairs followed by oil replacement. The most common test results show an increase in dissolved gasses (DG). These typically include hydrogen, methane, acetylene, ethylene, and ethane. High DG concentrations can explode when a unit is switched in and out of service.

Most sites simply hang a red lock on these units and identify them as “do not operate.” A solar string outage is the only way a crew can perform maintenance on the associated panels.

Recently, an oil-filtering method has come into the marketplace that may extend the life of transformers with high DG. This filtering process draws a vacuum on the oil reservoir and presses the oil through specialized equipment that removes the gasses and water from the oil. Results can be documented with a post-filtering oil sample analysis. This process, however, does not repair the transformer.

The breakdown of electrical insulating materials and related components inside the transformer generates the gases. Typically, the replacement cost of a pad mount transformer ranges from $25,000 to $60,000 depending on input and output voltages.

The transformer will still produce DG, but it may provide for an extended period of safe operation until the gas level becomes too high again. Periodic oil sampling will let an owner or operator know if this process results in months or even years of normal operation.

Transformer vaults are the pedestal pad-mount transformers rest on. An initial practice in the solar-farm construction industry was to set transformers on vaults made of fiberglass. In some instances, fiberglass vaults have proven inadequate. Inspections showed the transformers leaning, sinking, or moving past the limits of the cables buried beneath them. A typical response is to replace the fiberglass vaults with precast concrete vaults. This repair is sufficient to solve the problem for the life of the plant.

The collection system has several supporting components but the single most important one is the connecting MV cables. MV cabling runs between the pad-mount transformer at the exit of the inverter and substation, and is usually below ground.

Below-ground MV circuits can experience an occasional ground fault or splice failure. A ground fault may occur when a cable is damaged by a sharp or heavy rock. A “Thumper” is used to pinpoint the location of ground faults, with information from the fault recording relays in the substation. Damage is repaired with a new cable splice. Many cable splices from original construction remain below ground and are a common failure point in the cable. As a result, the original splices can fail. The repair method is the same as for ground faults. It is customary to make cable splice repairs above ground and cover them with a protective splice box.

This cable splice was made above ground and now resides in a protective splice box.

Substations for solar farms contain the most typical equipment found at any traditional utility substation. Transformers, breakers, switches, relays, and more are subject to regulatory protocols. These protocols determine the schedule and scope for inspections, and are in place to ensure safety to personnel and equipment.

The most useful tool again is the IR inspection camera because it can quickly identify loose or damaged connections within the substation. It is also important to ensure that potential safety risks, such as sufficient substation yard stone and weed control, are an essential part of the maintenance program. The yard stone serves several purposes but most importantly it provides a high resistance layer – insulation – between our foot and the ground. The weeds, if not kept under control, can quickly grow tall and may provide a path for a dangerous ground fault within the substation.

This IR image shows a loose or damaged connection in a substation.

A lot can go wrong on a solar farm and not all risks are found at the PV panels or in the tracking system. BOP equipment, including pad-mount transformers, splices, and others are as essential for getting solar-generated power to the grid as the PV panels. Damage to a single splice or cable and a solar array can go offline. BOP equipment should also receive routine inspections to optimize solar-farm operations.

The good news is that there are highly qualified third-party service providers available to perform all the necessary inspections and maintenance throughout a solar farm’s BOP.

Every Solar BOP require a planned Preventive and Corrective maintenance activity to eliminate such type incident, all planned activity carried out during non generating hours and resultant to reduce the down time and better performance.

BOP is the arteries of the whole PV plant and unless we take care of these regularly, we are bound to have issues and costly down times.