By Gena Gustin, sales with SolarTech Universal

There has been a lot of buzz about PERC solar cell technology, especially over the past year, with manufacturers large and small touting it. It has piqued the interest of many in the industry, but basic information surrounding the advanced technology has not been widely available. Here are the basics on PERC and what can be expected down the road for this technology.

What’s PERC?

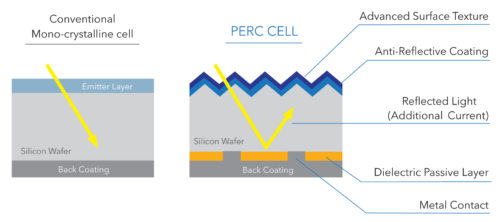

Depending on which source is consulted, PERC stands for Passivated Emitter Rear Cell, Passivated Emitter Rear Contact or even Passivated Emitter and Rear Cell. First developed in Australia in the 1980s by scientist Martin Green and his team at University of New South Wales, PERC technology adds an extra layer to the rear-side of a solar cell. Manufacturers spent many years focusing on the front side of a solar cell, and less attention was paid to taking advantage of production opportunities from the backside. Incorporating PERC into a solar cell boosts generation.

In order to create a PERC cell, an additional two steps are employed to the standard back surface field (BSF) during the manufacturing process. First, a rear surface passivation film is applied. Second, lasers or chemicals are used to open the rear passivation stack and create tiny pockets in the film to absorb more light. Manufacturers can approach this in different ways (i.e. varying the recipe for the film and opening technique), but in every instance a dielectric passivation layer is added to the back of the cell.

In order to create a PERC cell, an additional two steps are employed to the standard back surface field (BSF) during the manufacturing process. First, a rear surface passivation film is applied. Second, lasers or chemicals are used to open the rear passivation stack and create tiny pockets in the film to absorb more light. Manufacturers can approach this in different ways (i.e. varying the recipe for the film and opening technique), but in every instance a dielectric passivation layer is added to the back of the cell.

In employing just two additional steps, the return is threefold: 1.) Electron recombination is significantly reduced; 2.) More light is absorbed; and 3.) Higher internal reflectivity is experienced. Not all sunlight is absorbed through non-PERC solar cells (some light passes straight through). But with a passivation layer on the rear side of a PERC cell, unabsorbed light is reflected by the additional layer back to the solar cell for a second absorption attempt. This process leads to a more efficient solar cell. This is great news for those across the spectrum of the industry.

Why do solar cell and panel manufacturers care?

The investment to move to a PERC technology line requires minimal modifications to existing cell manufacturing lines. Manufacturers can easily make the jump to produce a superior product without having to outlay large capital expenditures for a complete overhaul of existing equipment. There has been a boom in adding PERC capacity to the global market and it is set to continue at a rapid pace for the next several years. Additionally, panel manufacturers are now able to produce a more energy dense module without much of an increase in build cost.

Why do developers, designers and installers care?

A SolarTech Universal solar panel

Panels incorporating PERC technology give more freedom to developers and designers, especially when dealing with unorthodox spaces or locations that were once thought to be less than desirable for solar. PERC panels have a higher energy density per square foot and perform well under low-light conditions and high temperatures. When considering total energy production rather than peak wattage, it is clear PERC panels are superior. Designers can utilize fewer panels to accomplish total output goals where footprint is limited, or they can dramatically maximize energy output if space is not a premium. It empowers designers to be more flexible and responsive to project objectives.

This freedom also allows the option to drive down BOS costs. More is being achieved with less, which can trickle down to significantly reduced soft costs. This can be the difference between a client having sticker shock and not moving forward with project to one seeing a cost-effective and manageable system. Additionally, more attractive temperature coefficients make PERC a top performer in hotter climates, and less thermal loss is experienced. This allows end users to achieve superior performance from their systems throughout the year.

Why do financiers care?

Being that PERC technology is neither new or radically different from standard cells, there is reduced risk on the financier’s side of the table to back an advanced technology. By utilizing a proven technology and modifying the standard cell, there is no change in the inherent risk of the module and its performance. Financiers should warm to the idea of panels manufactured with PERC technology. It sets a course for establishing dependable, long-term power output in a cost-effective manner for residential, commercial and utility projects. Total power generation over the lifetime of the solar system is increased without dramatically boosting the cost per watt.

What’s the future of solar cells?

Cell manufacturers were busy in 2015 expanding capacities to accommodate PERC demand from module manufacturers, and these trends have continued into 2016. PERC will be a mainstay for several years primarily because it does not require complete operation overhauls by current cell manufacturers.

There are other silicon cell types on the horizon set to propel panels into the next generation. One that has already been commercialized and is being utilized by U.S.-based PV module manufacturer SolarTech Universal is the heterojunction (HJT) bi-facial cell. The HJT cell fuses the best attributes from mono crystalline silicon cells (superior absorption) and amorphous silicon cells (excellent passivation) for a specialized cell that is immune to PID and LID. SolarTech Universal’s panels incorporating HJT cells achieve 300+ watts on the front side.

can PERC have better thermal stability compared with standard solar cells? and also can we measure the efficiency of energy conversion of the proposed solar cell model with PERC

Is it perc technology & Bifacial technology are same….

No. But bifacial modules often use PERC technology. Here’s more on bifacial: https://www.solarpowerworldonline.com/2018/04/what-are-bifacial-solar-modules/

Hi Kelly,

According to https://electrek.co/2017/12/19/florida-company-solar-cell-of-the-future-500w-heterojunction/

Tell Us What You Think!

Regards

Nick

Could you tell me your opinion on perovskites and how (or if) you believe it will ever take the place of silicon?

If perovskites SC has a better lifetime performance, and can be fabricated when exposed to air, it could be used in some flexible but small places in the future, due to the cheap materials superior increasing efficiency.

Flextronics uses PERC cells in there 285-295 mono panels.

Real and honest numbers?

What is the realistic power gain / perfomance gain (there is a difference!)

The advantage from the reflected light shall be dependent from the cell thickness which is around 160-180 microns. What I learned, the absobtion of most of the light is at ~40 microns depth.

I know SolarWorld Americas has PERC technology, as well as a new Bifacial module available for sale….

who else besides mentioned manufacturer have these panels available for shipment?

Hi John, Nearly every panel manufacturer now has a PERC line. They’re usually pretty vocal about including the technology in their newer modules.