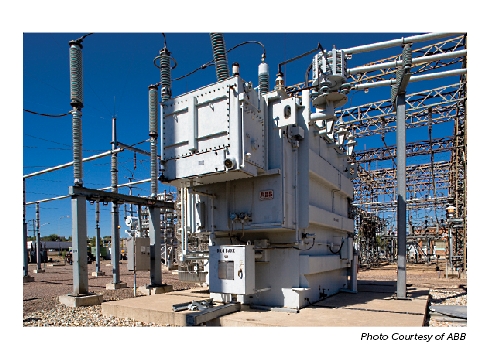

Transformers are critical components in solar energy production and distribution. Historically, transformers have “stepped-up” or “stepped-down” energy from non-renewable sources. There are different types of solar transformers including distribution, station, sub-station, pad mounted and grounding. All solar transformers have specialized needs that impact costs.

Transformers are critical components in solar energy production and distribution. Historically, transformers have “stepped-up” or “stepped-down” energy from non-renewable sources. There are different types of solar transformers including distribution, station, sub-station, pad mounted and grounding. All solar transformers have specialized needs that impact costs.

For example, solar power applications experience steady state loading during inverter operation. When the sun’s out, there’s a dampened reaction process and more constant loading on the transformer.

Also, fault ride through has not been defined for photovoltaic systems. This may be because it’s easier to turn solar systems on and off quickly, or because regulatory requirements have not caught up with the young technology. This may change in the future.

As for harmonics, the solar inverter’s typical harmonic content is below 1%, which has almost no impact on the system. The lower harmonic profile is because there are no generators and switching and protective controls such as those found on wind turbines. Solar transformers do require step-up duty. Yet, the solar inverter converts DC input from the PV array to AC voltage for the transformer in a smooth transition with no overvoltage from unloaded circuit. Because solar transformers operate at a steady voltage, with the rated voltage controlled by inverters, voltage and load fluctuations are considerably lower than in wind turbines. PV systems also operate close to their rated loads.

Solar-power systems also have special design issues. Because the largest solar inverter size is about 500 kilovoltampere (kVA), designers are building 1,000 kVA solar transformers by placing two inverter connected windings in one box. The transformer must have separate windings to accept completely separate inputs. Design issues also stem from running cables long distances to convert from DC to AC.

Restrictions on inverter size also limit the size of PV systems. Increasing the size by adding more solar inverters into one transformer box is extremely difficult. With the required box size and running cabling to convert DC to AC, things get complex.

The key to solar transformers is to understand the variables in every system. Transformers need to customize to work with each particular system. Inverter technology has been slow to advance, and it remains to be seen whether this comparative disadvantage will be a fatal flaw in the advancement of solar technology to the same level as wind farms.

The article may be a paid content – in reality lot of transformers connected to solar and wind farms are failing prematurely. Where the average expected age for a distribution transformer is about 25 years these last no more than 4 years or so and that is because there is no regulation of inverters and these spit out max harmonics and switching pulses which kills the transformers.

I completely agree with Mr. Suresh. I have also experienced the same. Harmonic during ramp up and ramp down time (with is about 2 to 3 Hrs) is about 5% to 9% average. According to manufacturer the overhaul harmonic level will be low it the load is steady. But they forget to consider Sun movement. Due to continuous changing angle of sun with reference to solar panel, the power generation is seldom constant. So, due to high harmonic in input to transformer the insulation stress is increased due to high dv/dt ratio with high order harmonic voltage. paper insulation will deteriorate in very short life then expected.

Pretty sure the Faraday Exchanger takes care of these problems!

because it is connected with multiple solar inverters hence reduces number of cables and complexity.

why solar application transformer has only double LV winding rather than single LV winding?