Of all the elements of a U.S. solar installation, the grounding portion of the system may well be the most important.

Of all the elements of a U.S. solar installation, the grounding portion of the system may well be the most important.

First, it is required to ground all PV systems. Second, a properly grounded system will help protect you and your employees from unintentional shocks and possible deaths. Third, it can help prevent fires in the system post-installation, avoiding potential lawsuits from angry homeowners. In other words, properly grounding your PV installation protects you.

Here are the basics you need to know to properly install a grounding system on your next PV array.

Two Types of Grounding

C.J. Colavito, commercial engineering manager and North American Board of Certified Energy Practitioners (NABCEP) certified solar PV installer for Rockville, Md.-based Standard Solar, says most installers are familiar with equipment grounding (EG), which is the more traditional and visable form of grounding. He says grounding is designed to keep installers — and anyone else who has to service the system in the future — from coming into contact with electrical current. Any metal or potentially conductive materials that are likely to be energized (having electrical current run through it) in the system must be grounded.

“If it’s metal, it needs to be grounded,” Colavito says. “That means the racking-and-mounting, junctions, frames — everything. If the steel bonding to your conduit is a metal pole, connect a copper conductor to it and conduct it to the ground. On PV systems, you always have to do equipment grounding — no one wants to be electrocuted.”

The second type of grounding is called system grounding, Colavito says. One of the two conductors coming out of the PV system will be grounded — normally it’s the negative wire. All system-grounded conductor wires must be white and are usually bonded to ground inside the inverter. It also includes a ground fault fuse to prevent fires within the system from excessive current flowing into the ground.

The Essentials Of A Grounding System

Andrew Truitt, principal of Truitt Renewable Energy Consulting in Denver, says a grounding system is only as strong as its weakest link, so all components are important. There are, however, a few components that are found in almost all PV grounding systems (as defined in the Article 100 of the National Electric Code (NEC)):

Grounding Electrode: “A conducting object through which a direct connection to earth is established.” The grounding electrode is usually a ground rod but can also be a UFER, underground metal water pipe, ground ring or any other means compliant with Article 250.52.

Grounding Electrode Conductor (GEC): “A conductor used to connect the system-grounded conductor or the equipment to a grounding electrode or to a point on the grounding electrode system. ” This is typically a wire that is sized based on the potential fault current that could flow through it if something went wrong in the electrical system. PV systems have separate requirements for both the DC and AC components, but both sets of requirements can often be met with one conductor (690.47).

Equipment Grounding Conductor (EGC): “The conductive path(s) installed to connect normally non–current-carrying metal parts of equipment together and to the system grounded conductor or to the grounding electrode conductor, or both.”

Truitt adds that both the GEC and the EGC must be sized according to the NEC guidelines and must be either a bare copper conductor or an insulated conductor with green insulation (with or without yellow striping).

The connection between the various components of the grounding system are equally as important as the items mentioned above, which is why it is crucial that all equipment used in a ground system (and throughout the entirety of the PV system, for that matter) be listed by a nationally recognized testing laboratory and installed according to the manufacturers’ specifications, Truitt says.

Grounding System Installation

As installers begin the installation of a grounding system, Truitt offers a few key elements to keep in mind:

Module Grounding: Like every other exposed metal component of a PV system, aluminum module frames must be grounded. There are many products available for grounding modules and just as many opinions about the optimal method. Truitt is partial to the most costly and time-consuming method: the tin-plated copper lay-in lug. He likes this method because it is the easiest method to install based on the “first to make, last to break” mantra of grounding (i.e. the grounding system should be installed before any current flows out of the PV modules and should remain in place until the modules are disconnected and all current flow has ceased).

Module Grounding: Like every other exposed metal component of a PV system, aluminum module frames must be grounded. There are many products available for grounding modules and just as many opinions about the optimal method. Truitt is partial to the most costly and time-consuming method: the tin-plated copper lay-in lug. He likes this method because it is the easiest method to install based on the “first to make, last to break” mantra of grounding (i.e. the grounding system should be installed before any current flows out of the PV modules and should remain in place until the modules are disconnected and all current flow has ceased).

Array Grounding Conductor Installation: The grounding conductor that runs within the array typically serves as both an EGC and the DC GEC and must be installed accordingly (690.47(C)). In most cases this can be accomplished with a solid bare-copper #8 wire. As the system size increases, it may become necessary to increase the conductor size as circuits are combined, and this must be done by irreversible means (250.64(C)) such as a copper crimp splice.

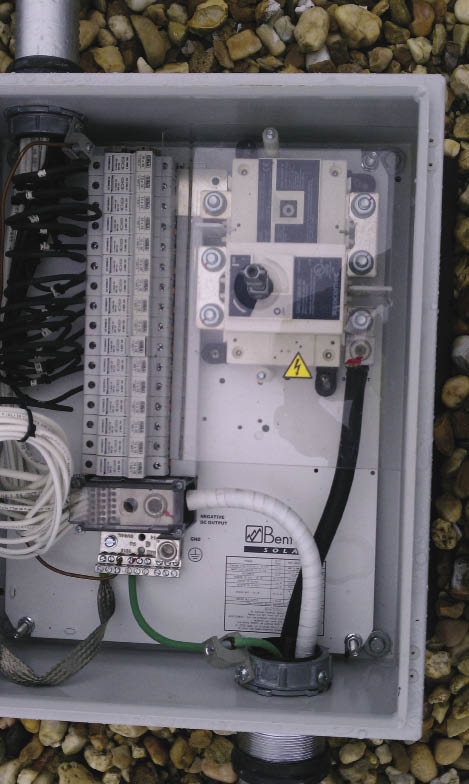

Enclosure and Conduit Grounding: All metal enclosures (boxes) and conduits that contain energized conductors must be properly grounded per the manufacturer’s instructions. This is typically done by routing the EGC/GEC through some type of “lay-in” connection that allows the grounding conductor to maintain its continuity. Different situations require different equipment grounding methods, so it is important to consult NEC Article 250 if any questions arise.

Grounding: Electrical systems that are grounded shall be connected to earth in a manner that will limit the voltage imposed by lightning, line surges, or unintentional contact with higher-voltage lines and that will stabilize the voltage to earth during normal operation.

Source: Article 250.4(A)(1), National Electric Code (NEC)

Ground Fault: A ground fault in photovoltaic (PV) arrays is an accidental electrical short circuit involving ground and one or more normally designated current-carrying conductors. Ground-faults in PV arrays often draw people’s safety concerns because it may generate DC arcs at the fault point on the ground fault path. If the fault is not cleared properly, the DC arcs could sustain and cause a fire hazard.

Source: Tech Topics: Photovoltaic Protection, Note 1, Issue 1 from Meresen, a global electrical component producer. Written by Ye Zha, Electrical Engineer and Robert Lyons Jr. Product Manager

System Ground vs. Equipment Ground: The National Electrical Code (NEC) requires that all PV Systems over 50 V have one current-carrying conductor connected to ground (690.41). The connection between that conductor (either the positive or negative DC conductor as well as the neutral conductor if the system has an AC component) and the earth is the system ground.

The NEC requires that all exposed metal parts (e.g. racking, conduit, enclosures) of PV systems (regardless of voltage) must also be grounded (690.43). This equipment ground is accomplished through the electrical interconnection (or bonding) of all those metal parts with the earth.

Source: Andrew Truitt, principal of Truitt Renewable Energy Consulting in Denver

Photos Courtesy of Standard Solar

In a solar system I can use the existing ground rod of the house or it is needed a aditional ground rod

My project is a standalone PV array system to power a ground sign (off-grid). ONE 185W PV array. TWO batteries. Ground sign has 25W of LEDs inside it. Controller. Timer. Does this need to be grounded?

Hi everyone,

This is a good place to learn.

I did a solar work recently and I grounded all strings and grounded the mppt on the same earth rod which is separate for the earth of the building. I hope this is right?

What is the value of the ground resistance for PV systems

does the system grounding & equipment grounding in solar system needs separate earthing point or we can bond both system & equipment grounding point at single grounding.

Should the metal eaves, metal step flashing, metal roof edging, brick lintels, storm window and door frames, and metal roof over porch be bonded?

I’m asking because the RMC carrying DC from array to inverter has direct contact to metal building components which are mostly or partly readily accessible to building occupants. Looked like code considered masonry building components capable of carrying current and during periods of rain all exterior metal may carry fault current.

Good idea. I will definitely add a section on

Solar power world..energymywaydevon.co.uk

Absolutely fantastic ! This needs to be LOTD! http://www.1stchoicesolar.org.uk