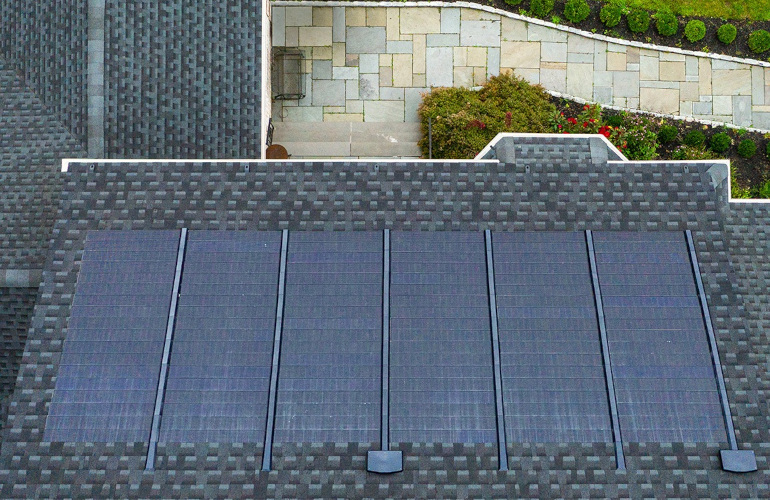

Standard Industries subsidiary GAF Energy has launched a new line of nailable solar shingles the roofing giant is calling Timberline Solar. The Timberline Solar Energy Shingle is made in GAF Energy’s 50-MW manufacturing facility in San Jose, California.

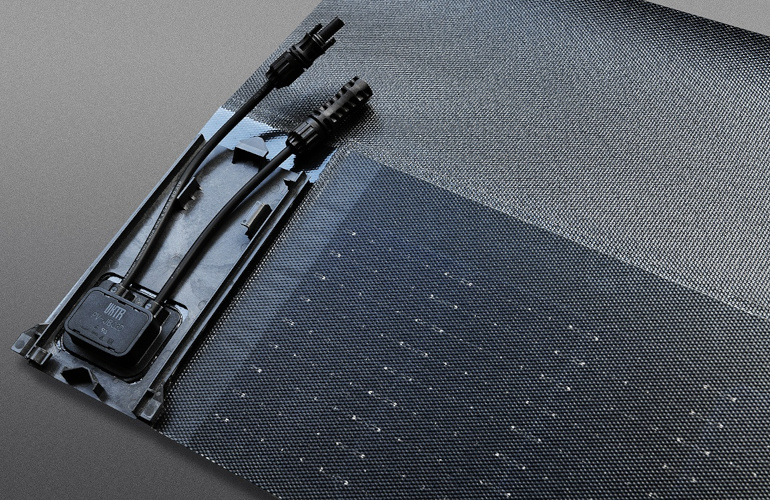

Each shingle is approximately 64 x 17 in. and 1-in. thick (with electronics), while the actual solar producing portion measures 60 x 7.5 in. The Energy Shingle weighs 10 lbs. and produces 45 W. See the data sheet here.

In September 2021, Timberline Solar achieved UL 7103 certification, which authorizes GAF Energy to install the system on residential roofs as a roofing product and a solar energy product. In addition, GAF Energy worked with Sandia National Laboratories, a U.S. Department of Energy research and development lab, to verify the product’s strength, durability, and overall market-readiness.

“Realizing our vision of a breakthrough mass-market solar roof has been our mission since we launched GAF Energy in 2019. What the team has accomplished is nothing short of extraordinary,” said David Winter and David Millstone, co-CEOs of Standard Industries. “Through our national roofing network, world-class talent, and aggressive investment in research and development, the Standard family of companies will transform the solar industry.”

GAF Energy has long seen Tesla and its solar roof as its biggest competitor in the building-applied photovoltaics market. While the Tesla solar roofing product uses a full roof of solar tiles and dummy glass tiles, GAF Energy has gone the route of incorporating its long solar shingles with traditional roofing shingles. The GAF Energy product appears to perform similarly to roofing competitor CertainTeed’s own attempt at solar shingles with the Apollo tiles.

GAF Energy’s Timberline Solar Energy Shingles can only be installed by GAF Energy certified installers.

Since DOW Chemical went out of business on their early solar PV tile offering, I have not been impressed with solar PV tile installations. NOW the NEC has additional RSD requirements in play at the panel level that pushes back against solar PV roof tile and going to a low racking of standard 380 watt crystalline silicon solar PV cells framed in a panel as a unit. Set this about 4 inches off of the roof for under panel heat removal and allowing an RSD device to be mounted under each solar PV panel is a better overall design, for both longevity and ease of repair over decades of use. At an average of 6.8kWp per 400 square foot of array area, the string solar PV panel set up is more effective at using roof space for solar PV daily harvest. At 45 watts for 472 square feet of roof space the tile product from GAF takes up more roof space and is nailed down to the roof with no air gap for heat dispersion which affects the tile panel’s effective harvest by up to 11% over a solar PV panel with an air gap. This would make the equivalent tile roofing of about 525 square feet of roof space to get a reliable 6.8kWp solar PV installation. You get about 7.7kWp with the tile covering around 600 square feet of roof space. With the 380 watt solar PV panel product filling in about 600 square feet of roof space, one gets about 10.6kWp out of those 600 square feet of roof space. Just sayin’ matching roof tile does not necessarily a good functional solar PV installation make.

How is GAF going to handle California allowing only C10 contractors to install solar? Roofing contractors would be better to handle the guarantee problems of roofing damage, etc. with others walking on them as well.