By Greg Shambo, VP of O&M sales, Borrego

When solar asset managers open their proverbial pockets to contract with a long-term O&M company, the opportunity to maximize solar plant performance is often doomed from the start. With a limited supply chain of critical replacement parts, a shrinking labor pool causing labor cost increases, and the looming realization that the financial models may be based on overly aggressive modeling, it’s easy to fall back on short-term fixes.

It’s been reported that the PV industry is operating at a 6% average production shortfall, and this type of single-digit shortfall can have a dramatic 40% reduction in equity cash flows over a 10-year period. As outlined in a recent webinar with Wood Mackenzie and kWh Analytics, many system owners have no choice but to narrow O&M scopes that are outsourced to third-party O&M service providers, opt to perform some elements internally or forgo them all together with the hope that it will all work out in the end.

This dynamic needs to shift to responsible long-term O&M planning to help system owners gain back the most financial value from their solar assets. Here are some key considerations for thinking long-term about solar plant performance.

Preventative vs. corrective maintenance

Asset owners know that preventative maintenance for solar projects is table-stakes for solar asset management — for long-term system health, corresponding asset value and ensuring that critical warranties on expensive equipment are not voided. As the WoodMac webinar suggests, preventative maintenance alone isn’t enough to maximize long-term solar plant performance and obtain the most value from an asset.

Corrective maintenance issues regularly arise, whether they impact availability. As an example, Borrego O&M manages over 1,000 PV sites totaling 1.2 GW across the United States. With these project sites under its care, Borrego has successfully executed 2,100 corrective O&M services needed in 2021 so far. These reactive issues occurred in approximately 57% of the Borrego fleet. In other words, half of the project sites under Borrego care required 4.2 “unplanned” services by the end of Q3-2021.

In Borrego’s experience, when corrective maintenance is prioritized over preventative care, we see a 2% overall raw availability increase in site performance.

There is a wide range of corrective O&M issues that we commonly see working on over 1.2 GW of large-scale solar power plants. The majority are system outages, utility and non-utility caused. Other common problems include failed termination, external damage, inverter failures with total replacement needed, and failed breakers, fuses or other internal components. These commonly occurring issues are some of the most significant causes of lowered system production, and they typically fall outside the scope of most preventative maintenance packages.

Beyond maintenance-related issues

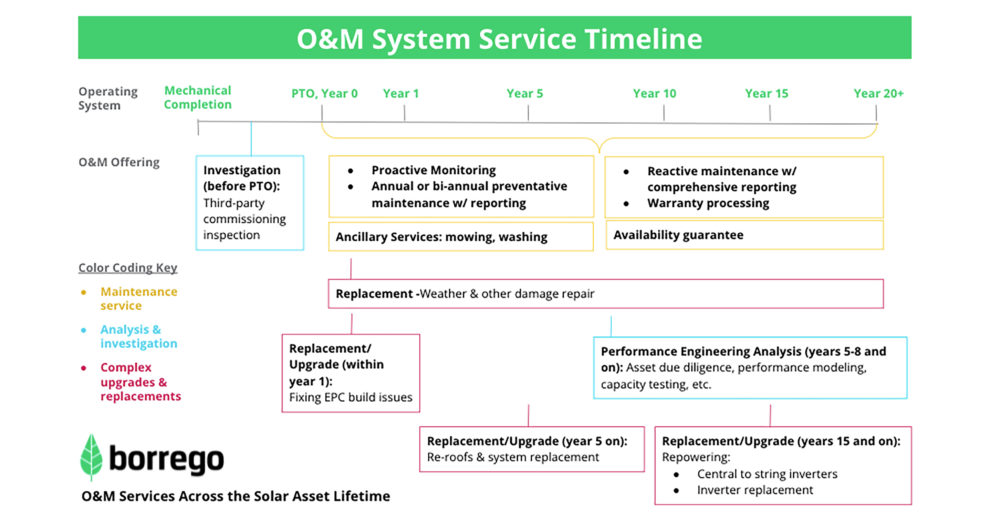

There are instances when an asset owner may need special O&M services, depending on the complexity and skills required to solve the cases that arise. These additional services can include performance engineering analysis, site investigations, upgrades and complex replacements. Some of these issues occur at specific times during solar asset operation, such as inverter-related replacements and upgrades around years 15 and on. Other O&M problems can occur any time during the asset life when needed, such as weather-related damage. The diagram below illustrates the most common O&M issues and service needs across the asset lifetime.

Here is a brief rundown of the timing and typical scope of some of the most common O&M repair services needed for solar power plants:

- EPC phase and Year 1

- For asset owners that self-perform O&M, lenders may require or find it beneficial to have a third party provide a commissioning inspection.

- Within year one, solar asset owners may need repair work from the EPC build. Borrego has seen failures from improper breaker torquing, loose bolts and poor underground cable installation.

- Years 5-8 and beyond

- For solar roof installations, it’s not uncommon to see requests around year five to remove systems, replace the roof and replace systems.

- Also, there is more demand for engineering performance analysis around year five. For example, Borrego performed an independent engineering analysis for SunRay that was ultimately used to meet its lender’s requirements. Borrego looked at historical performance, forecasted future performance and compiled recommendations to improve performance.

- Years 15 and beyond

- After year 15, one of the most common asset services is repowering, which is often accompanied by system upgrades for modules and inverters. It is often beneficial for asset owners to replace their central inverters with string inverters when repowering.

- Besides repowering, other issues arise with aging systems such as foundation crumbling, electrical equipment deterioration, etc.

- Any time

- As part of preventative maintenance services, necessary repairs or replacements may be identified that fall beyond the scope of standard preventative maintenance. During preventative maintenance work, Borrego’s skilled technicians often recognize issues and make recommendations to improve overall system health and performance.

- Additionally, performance anomalies or alerts routinely happen as part of proactive system monitoring, enabling an O&M provider to initiate and make corrective maintenance repairs.

- Weather-related damage can occur at any point in a system’s operation and are typically outside the maintenance scope. Examples of weather-related damage include water damage (e.g., water intrusion and corrosion); misaligned and degrading equipment from erosion changes; broken and damaged panels from lightning, hail and wind damage; and UV deterioration such as degraded and exposed wiring.

- With the increase in wildfires in recent years in the Western United States, additional washing may be needed to get the desired asset performance.

Maximizing performance of solar assets

These examples illustrate how a long-term mindset is needed to improve performance and system health issues and ultimately increase the value of solar assets. Borrego operationalizes this long-term mindset with a team of technical subject matter experts who investigate, troubleshoot, repair and upgrade large-scale solar systems. They draw from extensive field experience and technical analysis on the more than 1.2 GW that Borrego manages.

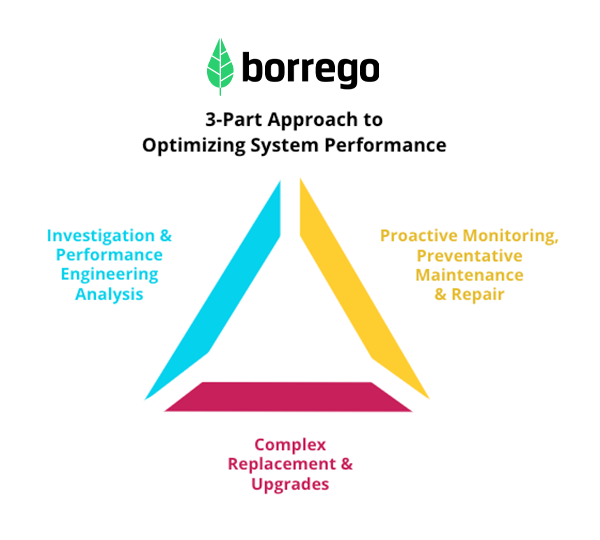

Borrego provides a three-part approach to its O&M service offerings to support customers with the three core areas facing their system’s performance across the entire solar asset lifetime:

- Investigation and performance engineering analysis

- Replacement and upgrades

- Proactive monitoring and preventative maintenance and repair

Greg Shambo brings a background in sales and marketing and more than 10 years of experience in renewable energy. Greg’s passion for improving the sustainability of the planet through renewable energy projects spurs his approach to building long-lasting relationships with customers and teams.

Greg Shambo brings a background in sales and marketing and more than 10 years of experience in renewable energy. Greg’s passion for improving the sustainability of the planet through renewable energy projects spurs his approach to building long-lasting relationships with customers and teams.

“This dynamic needs to shift to responsible long-term O&M planning to help system owners gain back the most financial value from their solar assets. Here are some key considerations for thinking long-term about solar plant performance.”

I would submit, the dynamic has already changed as in 2016 XCEL Energy found out while taking competitive bids for replacement of old coal fired assets, that several of the bids included solar PV or wind generation with BESS as part of the project. The projected amortization of the alternative asset was found to be less costly than continuing to use old coal fired plants to generate electricity. Now the practice of designing a solar PV farm as a serial D.C. generation asset is pushing the 1.5 to 1 D.C. to A.C. buss, single axis east to west tracking and larger BESS to handle longer periods of the day or night with energy generated or stored to use later in the day or into the night. SCADA and technology such as drones can monitor, report and control several acres to thousands of acres of generation be it solar PV or wind generation facilities.

What EPC entities need to ‘chase’ is the power of having an alternative but intermittent energy generation resource like solar PV or wind generation online and using BESS as the “makeup capacity” of the old fueled generation sites. The industry needs to “get over” the current accepted 2 to 4 hours of energy storage and start thinking 8 to 12 hours of something like redox energy storage to allow extended Battery backed intermittent resources to replace fueled Peaker plants for fast capacity services to the grid load demands. The energy bandwagon has pretty much accepted lithium ion battery packs as the energy storage of choice, now needs to take that deep dive into the grid as a whole and how and ‘where’ to apply something like very large redox flow batteries along the grid infrastructure to shuttle energy from one area to another in real time.

Well said Solarman. I really like the ideas you put in the last paragraph especially with the ability to shuttle energy from one area to another in real time.

We do need alternatives, but it’s good to see the industry as a whole is at least on the right path in some sectors.