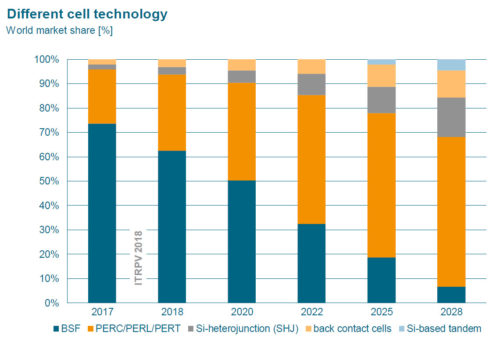

Solar Power World has previously reported on the various solar cell technologies trying to enter the mainstream. And indeed, PERC technologies, half-cell panels and bifacial modules are more than just buzzwords today. As indicated by Hanwha Q CELLS’ patent infringement claims against panel manufacturing competitors, the fight for market share of PERC panels is strong. In fact, ITRPV expects PERC (passivated emitter rear contact) cells to become the dominant solar technology by 2021, with it already securing more than 40% of the market today. Half-cell panels are still emerging but are expected to make up more than 10% of the global share of panels this year and nearly 40% of the market by 2028. The same with bifacial modules: As installation techniques are perfected, especially on utility-scale tracking projects, these dual-sided solar cells should also have 40% of the global market by 2028.

So what technologies are on the horizon? Keep an eye on TOPcon, HJT and IBC.

Credit: ITRPV

TOPcon (tunnel oxide passivated contact) is a newer solar manufacturing concept where a thin oxide layer is introduced to the silicon cell to reduce recombination losses and increase cell efficiency. HJT (heterojunction cell technology) combines the advantages of monocrystalline silicon solar cells (good absorption) and amorphous silicon thin-film solar (superior passivation) into one new cell, leading to increased efficiency and power yield. Meyer Burger has been perfecting HJT processes since 2010 and offers manufacturing equipment that uses lower temperatures and less energy than traditional manufacturing lines. IBC (interdigitated back contact) modules, which many popular brands already use, move all electrical contacts to the back of the cell, leaving the front of the module free of busbars and able to convert more light into energy.

Shankar G. Sridhara, CTO of REC Group, commented on the company’s leadership in half-cell technology since introducing it to the industry in 2014. He said REC also sees itself as a leader in HJT panels now with the world’s most powerful 60-cell panel (using HJT) at 380 W.

“HJT is becoming more interesting due to fewer process steps. The highest cell efficiency reported of 26.2% is based on HJT cell technology. The process, however, is not easy,” he said. “IBC technology is much more complicated compared to HJT, and for the very high-efficiency cells, it requires lithography. Therefore, it is much more expensive.”

Researchers predict that further efficiency and power increases can only come through advanced manufacturing techniques like TOPcon, HJT and IBC. As Sridhara noted, these new technologies do require more manufacturing expertise and expense though, so PERC will continue to reign supreme.

“[PERC is] a mature technology today, and there are many equipment vendors offering the equipment. The efficiency increase is quite significant (greater than 1% absolute) with only a couple of additional process steps in a standard cell production line,” he said.

While not showing quick gains like PERC, TOPcon, HJT and IBC should still comprise a substantial market share within 10 years as the industry continues to squeeze more power and efficiency out of solar panels.

Tell Us What You Think!