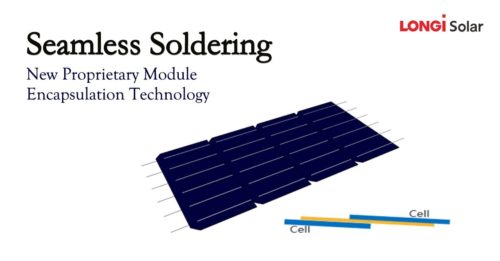

Chinese solar panel manufacturer LONGi Solar announced it has developed a “seamless soldering” technology that eliminates the gap between solar cells and increases the efficiency of completed PV modules. In traditional modules, conductive ribbons or busbars are soldered to each other to connect solar cells together into strings. Solar cells leave a slight gap in between each other to allow for these connections.

LONGi’s seamless soldering technology instead “tiles” the solar cells to each other (similar to how shingles are installed on a roof) and the ribbons appear to be fed underneath adjoining cells. The shingled layerment eliminates the 2-mm gap between cells and allow for more cells to be used in a traditional module footprint. Power output increases, as does efficiency, LONGi claims. According to a TÜV SÜD test on May 30, 2019, this seamless soldering technology, when combined with innovative module design, has the potential to push LONGi Solar’s high-efficiency PERC module power record to 500 W.

LONGi’s seamless soldering technology instead “tiles” the solar cells to each other (similar to how shingles are installed on a roof) and the ribbons appear to be fed underneath adjoining cells. The shingled layerment eliminates the 2-mm gap between cells and allow for more cells to be used in a traditional module footprint. Power output increases, as does efficiency, LONGi claims. According to a TÜV SÜD test on May 30, 2019, this seamless soldering technology, when combined with innovative module design, has the potential to push LONGi Solar’s high-efficiency PERC module power record to 500 W.

LONGi plans to use this new technology in mass production by the second half of 2019.

“This technology is perfectly compatible with existing module encapsulation processes and equipment. It has high mass production maturity and stability, and capacity is easily scalable,” said LONGi in a press release. “In addition, ‘Seamless Soldering’ has good technical compatibility that integrates with M6 monocrystalline silicon wafer, thin silicon wafer, soldering wire and reflective ribbon.”

LONGi has carried out intellectual property research on seamless soldering technology and has applied for a number of related patents.

Canadian Solar also has a “shingled” module line, released last year. The HiDM — high-density mono PERC — module is all-black with layered solar cells that remove that inter-cell gap. The 60-cell HiDM reaches 330 W and the 72-cell HiDM reaches 410 W. Their lower power can be attributed to their all-black design, but HiDM modules have an efficiency of more than 19.9%.

Got to see Canadian Solar’s new “shingled” module up close today! @Canadian_Solar @OSEIA_Solar pic.twitter.com/1gcS5jyrob

— Kelly Pickerel (@SolarKellyP) May 8, 2019

Tell Us What You Think!