This installation tip was provided by Jared Wiener, vice president of marketing for SolarRoofHook

Every solar installer must find a way to prevent the roof from leaking, but most are unaware of what’s happening with flashing technology. This isn’t surprising, since flashing typically makes up less than 5% of the total cost of a standard 7-kW install on an asphalt shingle roof.

As the industry continues to look for ways to reduce costs, successful companies will emphasize reducing labor costs over the raw cost of materials. Without sacrificing project security, one can save money by looking into the latest flashing innovation: Microflashing.

As the industry continues to look for ways to reduce costs, successful companies will emphasize reducing labor costs over the raw cost of materials. Without sacrificing project security, one can save money by looking into the latest flashing innovation: Microflashing.

For decades, installers have used similar flashing technology for asphalt shingle roofs, usually a rectangular piece of aluminum or steel slid underneath shingles and over the roof penetration. Recently, elevated flashing techniques using rubber bushings have come on the scene to provide an extra level of security on roofs.

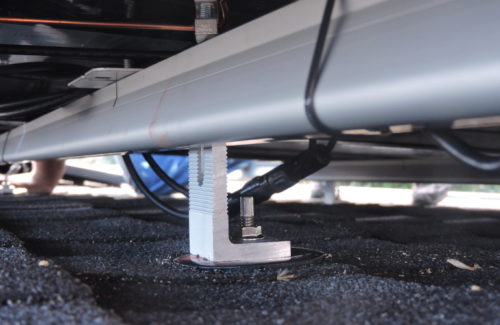

Enter SolarRoofHook’s innovative flashing technique of Microflashing. The product took lessons learned from previous flashing designs to address common installer issues: size of flashing, number of components and speed. SolarRoofHook’s QuickBOLT mounting system consists of three components: an EPDM rubber compression washer (called Microflashing), a bolt and a hex flange nut. When installers drive the bolt down, the collar compresses the Microflashing down onto the roof, creating a watertight seal. No lifting of shingles is needed. Any racking system can then connect to the bolt.

Microflashing allows for a smaller footprint, fewer components and a quick installation. In an ever-changing solar market, installers are looking for ways to be more cost effective, and exploring new flashing technologies is a great first step.

Tell Us What You Think!