Installing rooftop solar systems that consistently meet waterproofing code requirements rests on understanding the relationship between code, roofing manufacturers and best practice guidelines. This knowledge can make the difference between passing and failing an inspection, and it helps maintain any roof warranties as well as reduce long-term liability.

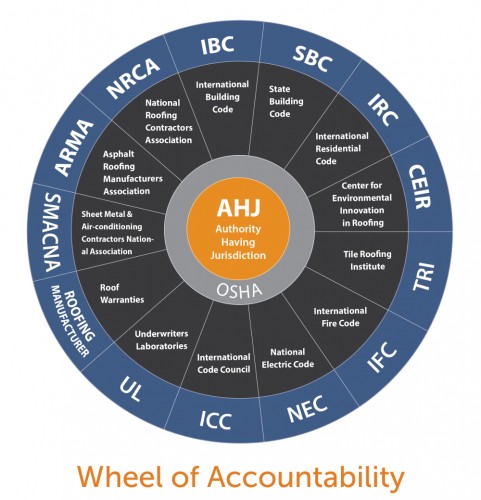

Quick Mount PV created the Wheel of Accountability to help solar designers and installers better understand the relationships between relevant codes, standards and best practices—guidelines that impact rooftop structures and waterproofing.

The AHJ (authority having jurisdiction)—typically the local building department—is at the center of the wheel. The AHJ has final say on how rooftop solar systems will be installed. The AHJ is empowered to interpret codes and standards and enact special requirements that address climatic, geological, seismological or topographical conditions unique to an area.

The AHJ (authority having jurisdiction)—typically the local building department—is at the center of the wheel. The AHJ has final say on how rooftop solar systems will be installed. The AHJ is empowered to interpret codes and standards and enact special requirements that address climatic, geological, seismological or topographical conditions unique to an area.

OSHA establishes workplace safety requirements and can shut down any jobsite or fine an installer for unsafe workplace practices.

The National Fire Protection Association (NFPA) publishes the National Electric Code that governs equipment-grounding requirements for PV systems. UL develops the UL 2703 standard for rack-mounted PV systems which outlines the proper methods for ensuring a reliable equipment ground for the modules and rack to minimize the potential for shock or fire hazard in the event of an accidental fault.

Building codes are developed by the International Code Council (ICC), which publishes the International Building Code and International Residential Codes, which are used as the basis for almost every State Building Code. Building codes require that all roof penetrations be waterproofed with flashing that complies with the roofing manufacturer requirement. The NRCA and ARMA publish installation guidelines used by the overwhelming majority of shingle manufactures, and the Tile Roofing Institute publishes flashing guidelines used by the vast majority of tile manufacturers.

The roofing manufacturer is included in the Wheel of Accountability, as building code establishes the manufacturer as the entity that determines proper flashing procedure. It is necessary to follow roofing manufacturer flashing installation instructions to comply with code and maintain the roof warranty.

This tip was contributed by Jeff Spies, senior director of policy of Quick Mount PV.

Can I install solar on a roof with multiple layers? The top layer is over 20yrs old.

what are the set backs from edge, top ridge and valley and on a flat roof, on a commercial roof and a residential roof ?

I heard from my City Council (San Rafael, CA) that the setbacks on a flat roof are 3 ft from the edge, so that fire fighters can walk around the panels without having to step on them.

You may want to call up your local inspector and confirm this.

I’ve been told that NFP codes require a PV panel setback from the edge of roof for fire fighting. What about solar PV shingles? DO I have to combine a std shingle with a PV shingle to meet code? 55113 zone 5 WIsconsin

Milton brings up an interesting point. The most recent NRCA guidelines for pipe penetrations require the flashing be integrated into the underlayment. This is only possible with new roofs. That said, the building codes require flashing per the shingle manufacturers requirements.

The largest shingle manufacturers have clear guidelines for flashing installation for solar penetrations. In fact, GAF (the largest shingle manufacturer) has approved only Quick Mount PV’s flashed mounts and Certainteed (the second largest shingle manufacturer) has approved Quick Mount PV flashings along with another manufacturers of metal flashed roof mounts.

Quick Mount PV has worked with every major shingle manufacturer (GAF, Certainteed, Owens Corning, Malarkey, Pabco, IKO, etc) to get approval for our metal flashing roof mounts.

Very few shingle manufacturers have approved non-metal flashings.

Now let’s address sheathing attached roof mounts. Most building officials and top structural engineers in the PV field question the legitimacy of sheathing attached mounts. While possible, it would be necessary to validate the attachment of the sheathing to the rafters. This can only be done on a reroof. On my roof, on two rafters under my array, I can see the staples that are supposed to connect the sheathing to the rafters missed two rafters all the way up the roof. This is not a big problem on my tile roof, but is a huge issue on a shingle roof.

Another concern for sheathing attached systems is load distribution. If the roof attachment is positioned too close to the corner of the sheathing, all the wind uplift loads get transmitted a single nail that connects the sheathing to the rafter. Wind uplift forces can exceed the holding power of this one nail. If a nail holding the sheathing to the rafter pulls up in a wind storm, there is both a structural and waterproofing concern.

Quick Mount PV has explored sheathing attached systems in the past and abandoned this approach. If a roof attachment needs to be positioned between two rafters, we advise installing wood blocking between rafters. We feel sheathing attachments are not structurally reliable.

There are very few roofing manufacturers that will provide flashing instructions specific for Solar Mounting.

Other roofing ,manufacturers may relate to the NRCA “guidelines” … the 2015 NRCA guidelines is the current version that is in place of the older first published in 2012. The 2015 current guidelines does represent how a pipe flashing must be installed. (with the upper flange underneath the roofing paper) which is the only way for this flashing to become effective (Water shedding only)

So what this still mean?…that if the roof manufacturer suggest the installers to go by the NRCA guidelines remember that is not code), we know what happens right? New Roof! (The underlayment must be above the upper flange of the pipe flashing.)

The specific code (IBC and IRC) for flashing of shingle roofs (steep slope) doesn’t call flashing for solar supports. It calls flashings for other things such as pipe flashing etc…so we are back to

The code (IBC and IRC) for “rooftop mounted structures” still written that the installer must follow the instructions provided with the product.

I still think that a third party evaluated “flashing system” is the way to go.

Roof Tech realized the importance of such and about 2 years ago we finalized our ICC ESR 3575 report which is posted online.

Another test we have done aside from the ICC was with the mounting with the integrated flashing (RT Butyl) under water 6″ for 6 hours.